Explore the pivotal role of a fulfillment center in improving your logistics, ensuring faster deliveries, and better customer satisfaction with Ware2Go.

Explore the pivotal role of a fulfillment center in improving your logistics, ensuring faster deliveries, and better customer satisfaction with Ware2Go.

Learn the difference between a fulfillment center, warehouse, and distribution center — plus how they all work together to build an efficient fulfillment network.

With customers expecting increasingly fast shipping, traditional warehousing solutions often struggle to keep up. As the owner of a fast-growing brand, it’s a challenge you’ve likely run into yourself.

That’s where fulfillment centers, the unsung heroes of the supply chain, can help. This article explores how these third-party logistics (3PL) services, used by Fortune 500 companies, are more than just storage spaces. You can use them to provide seamless order processing and 1-to-2-day shipping windows for your eCommerce business.

By rethinking your approach to fulfillment solutions, you can transform your logistical challenges into strategic opportunities for growth. That’ll help ensure that your business continues to exceed the expectations of modern consumers.

Fulfillment centers (FC) are warehousing facilities often run by a third-party logistics (3PL) company. Inventory is received, put away, and stored by the fulfillment center until customers make another order. When fulfillment providers receive an order, they pick, pack, and ship the product to the end customer.

Fulfillment warehousing typically isn’t intended for long-term storage. The longer that inventory sits on the shelf, the less profitable it is for you. That makes managing your inventory and prioritizing high-velocity SKUs more critical than ever.

Different types of products have different requirements for warehousing and fulfillment. A fulfillment company sometimes specializes in certain product types, including:

There are also some unconventional models, like using stores as fulfillment centers.

The explosion of eCommerce and the decline of in-store shopping during the pandemic led many retailers to fulfill eCommerce orders directly from their stores. This major change required some reorganization and retraining of employees by retailers. But companies like Target turned their large store spaces into a competitive advantage.

According to report by McKinsey, shoppers expect a similar experience whether they’re shopping in-person or with online stores. Target’s ability to pivot stores into fulfillment warehousing centers allowed them to offer home and curbside pickup options.

If you’re considering using a fulfillment center, you’re most likely handling your warehousing and fulfillment in-house right now. Let’s look at what you’ll gain by switching to a fulfillment center and some potential drawbacks to consider.

Choosing fulfillment centers over self-fulfillment can offer several advantages. Here they are:

While fulfillment centers offer many advantages over self-fulfillment, there are a couple of trade-offs to consider:

Now that you know the advantages and disadvantages of fulfillment centers, let’s talk about how they differ from warehouses and distribution centers.

The terms ‘warehouse,’ ‘fulfillment center,’ and ‘distribution center’ are often used interchangeably. But within the transportation and logistics industry, the term ‘warehouse’ refers to the building where the products are stored. A ‘warehouse’ is called a ‘fulfillment center’ or ‘distribution center’ based on its capabilities.

Learn more about warehousing and fulfillment warehouse strategy with our 2024 Guide to Strategic Warehousing.

What are fulfillment centers in relation to distribution centers?

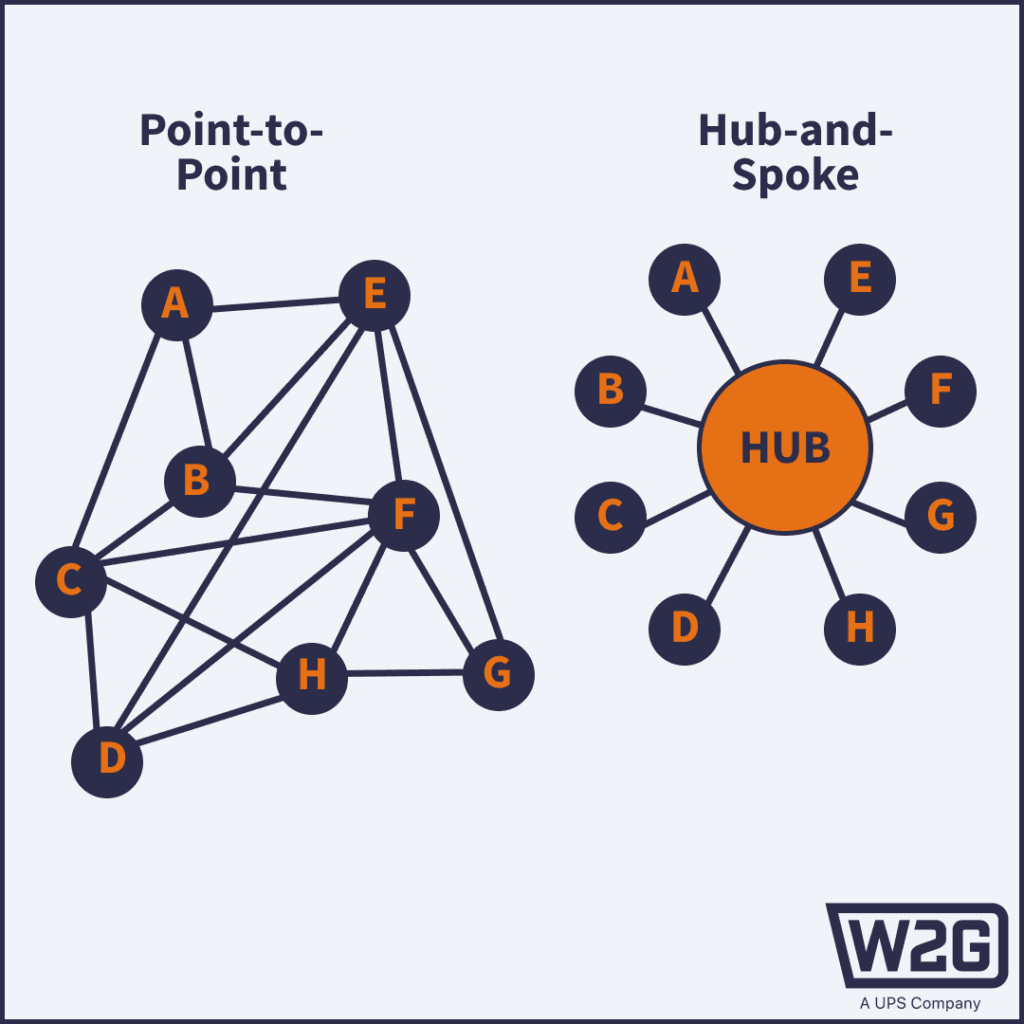

A distribution center acts as a hub within a network of fulfillment centers. For products manufactured overseas, a distribution center is often the first stop for inventory when it lands in the US.

In a hub and spoke fulfillment model, a distribution center takes inventory and strategically distributes it to fulfillment centers nationwide. The hub and spoke model gives your fast-growing brand more control over your inventory distribution.

No products go directly from a distribution center to the customer. You can think of the distribution center as the main internal fulfillment center that only exists to support all other fulfillment centers.

For example, imagine that your product sales surged in a specific area of the country. The hub and spoke model decreases the risk of stockouts by quickly channeling extra inventory from the distribution center to that area. The hub and spoke model also lowers the risk of making expensive long-zone shipments when demand spikes suddenly.

Q: How do fulfillment centers adapt to seasonal demand fluctuations?

A: Fulfillment centers can quickly scale your storage space up and down as needed. They also use software with advanced forecasting to manage inventory levels and meet seasonal demands. These features allow fulfillment centers to deliver your product promptly while minimizing the risk of excess inventory and stockouts.

Q: Can fulfillment centers handle international shipping?

A: Yes, many fulfillment centers can manage international shipping. They offer global shipping solutions while helping you navigate the complicated world of customs, shipping rates, and regulations.

Q: What advanced technologies do fulfillment centers use to enhance efficiency?

A: Fulfillment centers use AI, machine learning, and robotics technologies. These tools help optimize every step of the fulfillment process — from warehousing and order processing to item tracking — for an overall more efficient process.

Q: How do fulfillment warehousing centers ensure product safety and security?

A: Fulfillment centers use strong security measures to help keep your products safe throughout the fulfillment process. These include surveillance cameras, access control, and inventory management systems to cover all safety elements.

Q: Can a fulfillment company support custom packaging and branding needs?

A: Many fulfillment centers offer customized packaging solutions. Custom packaging can help your business improve your brand through personalized packaging and branding elements.

There are many advantages to fulfillment centers compared to self-fulfillment centers, such as relieving you of the stress of stockouts, overstocking, and dead stock. A fulfillment center can help with your business growth and provide a way for you to meet customers’ delivery expectations with faster shipping.

Using machine learning and AI, Ware2Go’s network optimization tool, NetworkVu, shows you exactly where to place your inventory to get closer to your end customers. This lowers time in transit (TNT) on final mile deliveries for faster, more affordable shipping.

Download our step-by-step guide for more insights on creating a better fulfillment network and higher customer satisfaction.