Inventory management can be incredibly demanding. You’ve got to be able to maintain oversight throughout the production process, track items across multiple fulfillment centers, and move inventory across your network seamlessly to keep things running smoothly and make customers happy.

However, managing these priorities becomes complex and challenging without an effective inventory management strategy that includes a clear finished goods inventory measurement. You risk losing connection to an essential signal that indicates your inventory’s “health” or status.

Read on to learn about the importance of finished goods inventory, how to calculate finished goods inventory step-by-step, and get tips on optimizing your inventory management.

What is Finished Goods Inventory?

Finished goods inventory represents the total stock of products ready for sale and available to fulfill customer orders. By applying the finished goods inventory formula, sellers can determine the total value of these ready-to-ship items.

Knowing your finished goods inventory is essential to understanding what you’ve got available and what you’re in a position to deliver to consumers. Keeping an eye on this metric enables you to:

- Keep waste down

- Prevent stockouts

- Drive operational efficiency

- Optimize inventory management processes

Fortunately, calculating your finished goods inventory is a relatively straightforward process. You’ve just got to have a few basic pieces of data on hand.

How to Calculate Finished Goods Inventory in 4 Steps

You can calculate your brand’s finished goods inventory in four basic steps. You’ve got to decide the time period you want to use, collect your data, calculate your cost of goods manufactured (COGM) and cost of goods sold (COGS), and then apply that data to your finished goods inventory.

But before we explain those steps, let’s examine the inventory formula for the finished goods.

Finished goods inventory formula

Running out of stock — or sitting on too much of it — is usually a sing of one thing:

You don’t have a clear picture of your finished goods inventory.

This formula helps solve that lack of visibility, showing exactly how much product is ready to sell at the end of a given period. Once you’ve nailed down your COGM and COGS, finished goods inventory calculations flow seamlessly from there.

The formula looks like this:

- Finished goods inventory = Beginning finished goods inventory + (Cost of goods manufactured – Cost of goods sold)

COGM represents the total production costs incurred to manufacture finished goods. This includes raw materials, direct labor, and overhead costs. COGS is the total cost of inventory sold during the period.

Step 1. Decide your time period

First, you’ve got to choose a period of time to compare your inventory levels. To ensure accuracy, you’ll need to select a comparable period of time and use that same period for all of your calculations.

For example, you could compare your finished goods inventory in Q4 of your accounting period in 2024 versus Q4 of 2023. That would enable you to look at your inventory at the end of each calendar year for a like-for-like comparison.

Step 2. Collect your data

Before you can calculate your COGS and COGM, you’ll need to collect the pieces of data required to complete each of those formulas as they apply to your chosen time period.

That includes the following data points:

- Beginning WIP inventory

- Ending WIP inventory

- Total manufacturing cost

- Beginning inventory

- Ending inventory

- Purchases during the period

- Value of previous period’s finished goods

After you’ve found these pieces of data, you’re ready to work out your COGM and COGS.

Step 3. Calculate your COGM and COGS

To work out your cost of goods manufactured (COGM), you’ve got to take the sum of your beginning WIP inventory and manufacturing cost and then subtract your ending WIP inventory from that total.

The formula looks like this:

- Cost of goods manufactured (COGM) = (Beginning WIP Inventory + Total manufacturing cost) – Ending WIP inventory

Next, it’s time to calculate your cost of goods sold (COGS). Add your beginning inventory to the total purchases during that period and subtract your ending inventory from that number.

Here’s the COGS formula:

- Cost of goods sold (COGS) = (Beginning Inventory + Purchases During the Period) − Ending Inventory

Once you’ve calculated your COGM and COGS, you can finally work out your finished goods inventory.

Step 4. Calculate your finished goods inventory

It’s time to apply your COGM and COGS to the finished goods formula. Find the difference between your COGM and COGS, then add it to your beginning finished goods inventory.

The amount you’re left with is your finished goods inventory for the time period you’ve chosen to look at.

Finished goods inventory example

Finding this complex? We’ve covered a lot of numbers and calculations in a short time, but don’t let that put you off. Let’s create a quick example of these steps in action.

Suppose you run a small business selling wellness products and want to work out your finished goods formula year-on-year. Here’s how you’d do it:

- Step 1: You want to compare your finished goods inventory for FY 2024 to FY 2023 to ensure that your operational budget for 2025 is on track.

- Step 2: You collect your data. Let’s say your beginning WIP inventory was $1,000, ending WIP inventory was $250, the total manufacturing cost was $350, the beginning inventory was $150, the ending inventory was $100, the value of the purchases made during the period was $750, and the value of the previous year’s finished goods was $150.

- Step 3: Next, you’ll calculate COGM and COGS. Using the numbers you collected in step 2, you’d get a COGM of $1,150 and a COGS of $800.

- Step 4: Finally, calculate your finished goods inventory. Subtract your COGS from your COGM, then add it to the previous year’s finished goods.

That means your finished goods inventory is $500.

By working out your finished goods inventory, you can better manage your inventory. You’ll also be able to fulfill various financial reporting and accounting purposes that every business owner needs to keep up-to-date on.

Using Finished Goods Inventory for Financial Reporting

If you’re a creative seller with an entrepreneurial spirit, financial statements might not be your favorite part of business ownership. But by working out your core financials, you’ll better understand your top-line and bottom-line revenues and what you’ve got to invest and scale up.

Understanding your finished goods inventory plays a significant role in achieving these outcomes.

Here’s why:

Determining gross profit

Finished goods inventory is a significant component of your cost of goods sold (COGS), which you need to know to determine gross profit. Errors in finished goods inventory values can inflate or deflate COGS, distorting your profitability metrics.

For example, let’s say your company’s finished goods inventory is understated. That means your COGS value will appear higher than it should, making your business seem less profitable than it actually is. That could detract investment or keep you from capitalizing on potential growth opportunities.

Establishing balance sheet integrity

Finished goods inventory is recorded as a current asset on the balance sheet, so it’s important to always have an accurate finished goods inventory on hand.

An inaccurate valuation can skew your company’s asset value, misrepresenting your financial position. Overstating inventory may suggest a stronger financial position than reality, while understating it can reduce investor confidence.

You need an accurate finished goods inventory to give investors, creditors, and stakeholders a genuine representation of your business’s performance.

Simplifying profit margin analysis

Mistakes in your finished goods inventory can also affect your profit margins. That makes it much harder to accurately assess product performance and the success of your pricing strategies.

By using precise inventory tracking and maintaining an up-to-date finished goods inventory for given time periods, you can reveal the most profitable popular products and which ones might need pricing adjustments or be retired from your catalog completely.

Managing cash flow

Finished goods mean tied-up capital. As a result, inaccurate tracking will probably cause you to miscalculate your available working capital, leading to potential cash flow challenges.

According to Mike Tuan, Founder of The Cushion Lab, a healthy cash flow is essential to achieving growth. That’s why The Cushion Lab leveraged Ware2Go’s variable cost, pay-as-you-go fulfillment model to minimize its capital expenditures.

“Cash flow is the key so we can continue to invest it back into developing new products, growing our team, and acquiring new customers,” he says.

“Ware2Go’s on-demand model allowed us to keep CapEx low in the supply chain so we could invest it back into growth.”

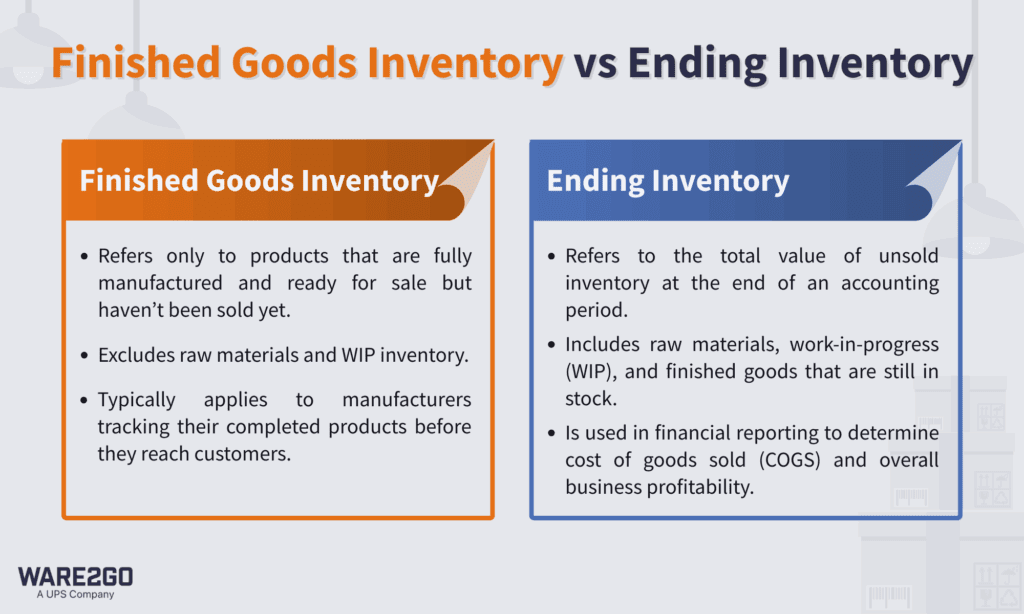

How is Finished Goods Inventory Different From Ending Inventory?

Some people tend to confuse finished goods inventory with ending inventory, and it’s not hard to see why. After all, they sound pretty similar. But you should be aware of a couple of fundamental differences.

Ending inventory refers to the total value of unsold inventory at the end of an accounting period. That includes raw materials, work-in-progress (WIP), and finished goods in stock. It’s used in financial reporting to determine the cost of goods sold (COGS) and overall business profitability.

By contrast, finished goods inventory only includes products that are fully manufactured and ready for sale but haven’t been sold yet. Unlike ending inventory, finished goods inventory excludes raw materials and WIP inventory.

Finished goods inventory normally applies to manufacturers tracking their finished products before they reach customers.

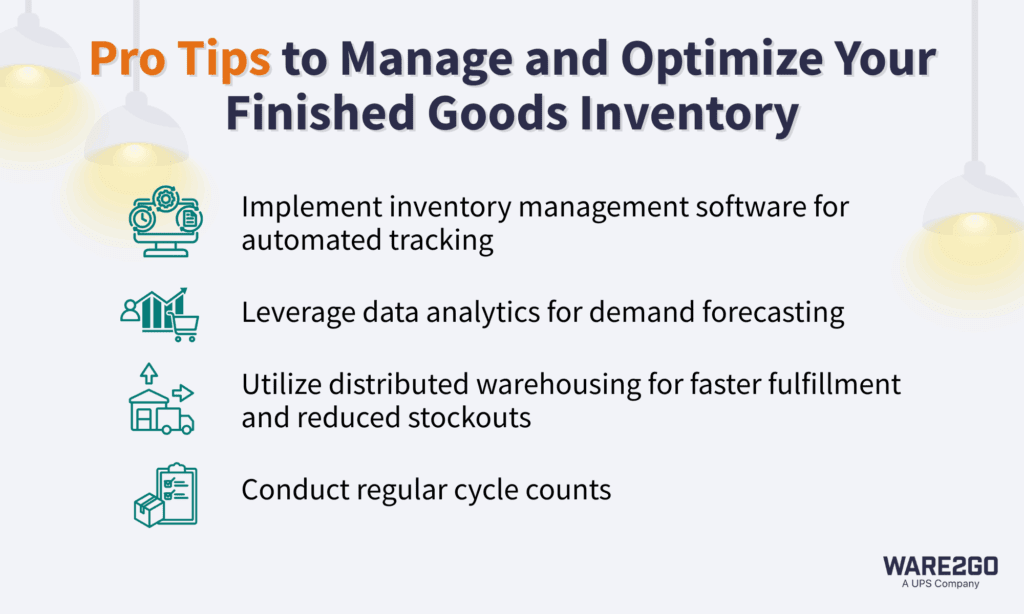

4 Pro-tips to Manage and Optimize Your Finished Goods Inventory

Optimizing your finished goods inventory doesn’t have to be difficult. You’ve just got to develop effective strategies and find the right partner that can help you optimize your inventory management workflows.

To help you get started, here are four pro tips.

Pro-tip #1: Implement inventory management software for automated tracking

To maintain an accurate finished goods inventory, you’ve got to implement an automated tracking system. That’s where inventory management software comes in.

Inventory management software provides real-time visibility into finished goods inventory, automating key processes to minimize human error.

An effective inventory software solution should include:

- Barcode or RFID integration: This enables you to automate inventory updates with each movement.

- Automated reorder points: System alerts when stock levels get low, helping you prevent stockouts.

- Multi-channel synchronization: This ensures inventory updates are made across all sales channels.

- Integration with fulfillment partners: Direct data sharing with providers like Ware2Go supports streamlined order fulfillment.

Check out the plant-based protein brand Aloha to see how inventory management software can streamline your workflows.

With FulfillmentVu’s self-service portal, they can input their own data or connect their sales data through direct integration with Shopify and BigCommerce. That means the Aloha team can generate a full report to identify new sales opportunities, reposition inventory, and optimize their network.

Pro-tip #2: Leverage data analytics for demand forecasting

Advanced analytics tools can analyze historical sales trends, seasonal patterns, and external factors like market trends or promotional cycles to forecast customer demand accurately. Armed with analytics, you’ll be able to:

- Forecast inventory: Analytics helps identify slow-moving products to reduce overstock.

- Reduce stockouts: Anticipating future demand spikes allows for proactive inventory replenishment.

- Enhance supplier management: Improved forecasts help you plan production and delivery schedules.

That’s why O2 Recovery decided to partner with Ware2Go.

O2 would often be completely sold out at gyms when a re-stock order was placed–until they could leverage Ware2Go’s technology-enabled fulfillment network. This enabled them to improve inventory forecasts, reduce stockouts at gyms, and fulfill replenishment orders within 1-2 days.

Pro-tip #3: Utilize distributed warehousing for faster fulfillment and reduced stockouts

Distributed warehousing places finished goods inventory closer to key customer hubs, improving delivery speed and reducing transportation costs. That means you’ll be able to:

- Ship faster: Strategic inventory positioning supports faster delivery times.

- Diversify against risk: Reduced dependence on centralized inventory operations insulates your business from supply chain disruptions and shrinkage.

- Realize cost efficiency: Minimize last-mile delivery costs by shipping from closer facilities.

For more best practices, check out Cambridge Audio.

By forward-stocking its inventory across three strategic Ware2Go warehouses, the UK-based brand reached retailers on the East Coast within two days. As a result of those increased service levels, Cambridge Audio has grown its overall sales by 98% year over year.

Pro-tip #4: Conduct regular cycle counts

Regular cycle counts ensure ongoing inventory accuracy without needing a full warehouse shutdown, and you can use a range of methods to ensure your stock accuracy is always on point.

This includes:

- Segment inventory by value or volume: Prioritize high-value or fast-moving items for more frequent physical counts.

- Schedule counts strategically: Conduct accurate inventory counts during slower sales periods to minimize disruptions.

- Leverage technology: Use handheld scanners or RFID systems to streamline the process.

Need a hand? Ware2Go’s 99.9% inventory cycle count accuracy and streamlined processes can help you make the most of your perpetual inventory system.

Ready to Optimize Your Inventory Management?

Understanding your finished goods inventory is a critical aspect of inventory management. It tells you exactly what you have on hand at the end of a set time period, allowing you to plan for the future and optimize your processes to avoid stockouts or excess stock.

However, calculating finished inventory is only one tool your business can use to streamline inventory management. Ware2Go can support you with the rest.

By partnering with Ware2Go, you can leverage our unique, plug-and-play fulfillment technology to evaluate historical and seasonal demand and gain recommendations on inventory placement, reorder points, and safety stock levels.

Discover how partnering with Ware2Go can simplify and streamline your inventory management.