Businesses can live or die based on how they handle inventory.

Two-thirds of customers say they’ll abandon a retailer and take their business elsewhere if they hit a roadblock online or in-store, such as experiencing a stockout. But on the flip side, overstocking and inefficient processes can overstretch your capital, require more complex infrastructure, and lead to obsolescence.

Success hinges on striking a healthy balance, and that’s why an effective inventory management plan is essential.

Inventory management is the process of controlling, overseeing, and optimizing your company’s inventory to make sure you’re minimizing costs and meeting the demand of your customers. But there are a range of strategies and methods you can deploy to improve inventory management.

Read on to learn why inventory management is important, explore the key elements of creating your own inventory management plan, and get pro tips on how to optimize your inventory management plan.

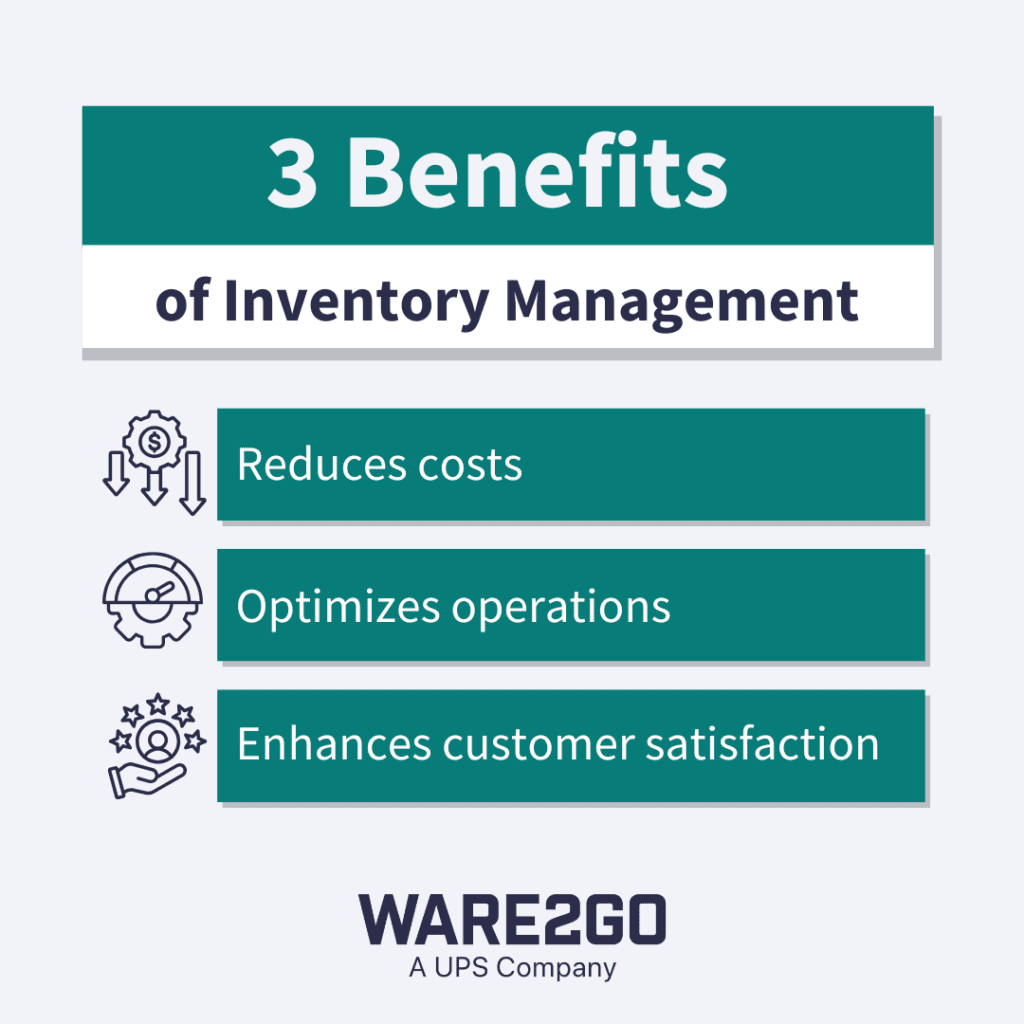

Why is Inventory Management Important?

Inventory management sits at the core of an efficient, cost-effective supply chain. When managed properly, the right products are available at the right time, in the right quantity, in the most effective location—without tying up unnecessary capital or straining warehouse resources. For growing businesses, optimizing inventory management can be the key to unlocking scalability and long-term profitability with the following business outcomes.

- Reduced costs: By avoiding overstocking, businesses improve inventory turns and reduce storage expenses. They will also minimize waste from obsolete or expired goods and free up capital that would otherwise be tied up in slow-moving inventory. Additionally, better forecasting reduces the need for costly rush orders or excess warehouse space, driving down operational expenses.

- Optimize operations. A well-managed inventory system streamlines the entire supply chain. With accurate data and forecasting, businesses can better coordinate with suppliers, reduce order processing times, and respond quickly to shifts in demand. Inventory management systems also reduce the likelihood of human error by automating tracking and replenishment processes. This leads to fewer disruptions, less downtime, and more reliable fulfillment.

- Enhance customer satisfaction. At the end of the day, inventory management directly impacts your customer experience. When inventory is well-aligned with demand, products are available when customers want them, and inventory is ideally forward stocked closer to the end customer to reduce delivery times. Orders are fulfilled more quickly and accurately, and cost savings from operational efficiency can be passed on to customers through more competitive pricing.

In a market where customer expectations and operating costs are higher than ever, efficient inventory management can be a powerful differentiator.

What are the Key Elements of an Inventory Management Plan?

An inventory management plan is your roadmap to keeping stock levels aligned with customer demand while minimizing costs and maximizing efficiency. It’s more than just knowing what inventory you have on hand—it’s a structured approach to managing the movement of inventory through your supply chain. While every business will have its own nuances, there are core components that every effective inventory plan should include:

- Clear objectives

Your plan should align with broader business goals—whether that’s minimizing inventory carry costs, improving delivery speed, reducing stockouts, or supporting growth into new markets. Clear goals and understanding your risk tolerance help guide decisions across every aspect of inventory planning. - Inventory categories, classifications, and valuations

Not all inventory is created equal. Each SKU will move at a different velocity, have unique storage and handling requirements, and realize varying levels of margin per sale. Understanding this helps prioritize management efforts, especially when applying inventory models like ABC analysis. - Defined inventory levels

Establish thresholds for each product, including reorder points, safety stock minimums, and maximum stock levels. These benchmarks help maintain balance, ensuring you’re neither understocked nor overstocked, both of which can be costly. - Demand forecasts

Use historical sales data, seasonal trends, and market insights to predict demand. An advanced demand forecasting model not only helps determine how much inventory to keep on hand but where to store it for fast and efficient delivery. - Inventory management systems

Technology is critical to execution. Whether it’s a dedicated inventory management system, an integrated ERP, or tools like RFID scanning, your plan should detail how you’ll track and manage inventory in real time. - Clear inventory policies

Work with your fulfillment partner to understand standard procedures for ordering, receiving, storing, and auditing inventory. Clear policies ensure consistency, reduce errors, and support compliance with internal and external quality standards. - Key Performance Indicators (KPIs)

Track what matters. Use KPIs like inventory turnover, stock accuracy, order cycle time, and carrying cost to measure progress and refine your strategy over time.

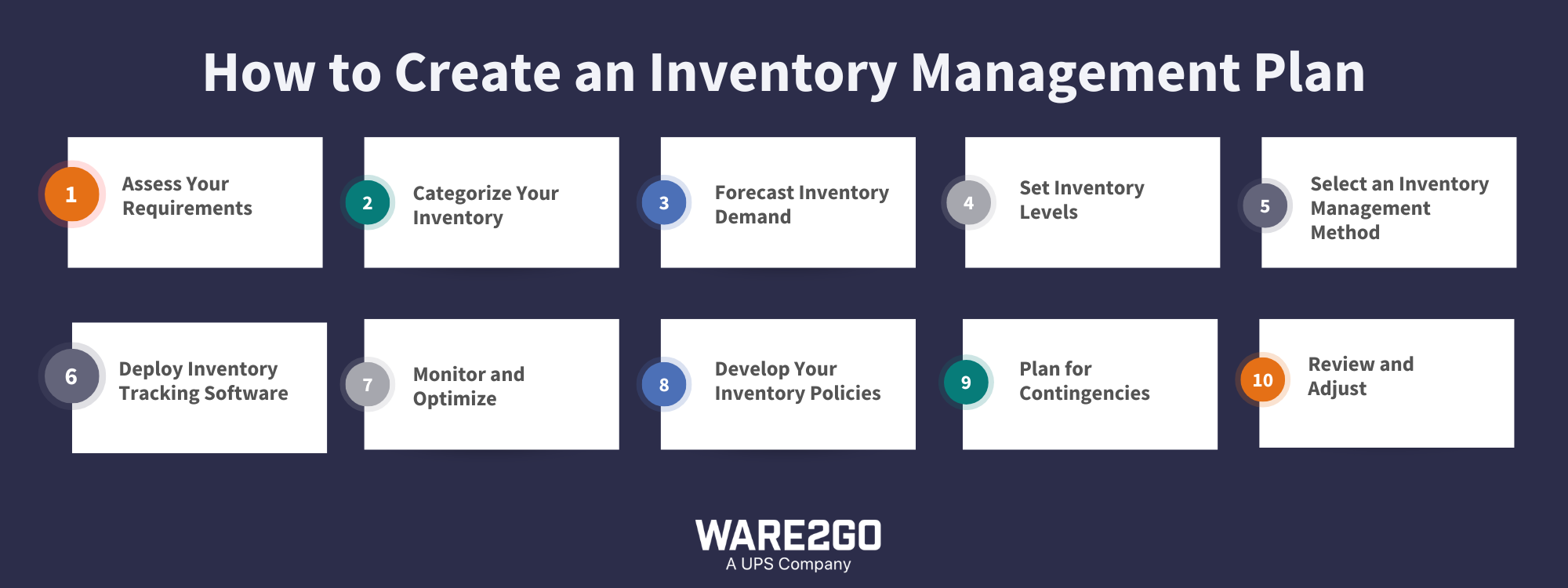

How to Create an Inventory Management Plan

Now that you understand the key elements of an effective inventory management plan, it’s time to put it into action. Creating a solid inventory management plan isn’t just about choosing software—it requires a step-by-step approach that aligns with your business strategy, operational needs, and customer expectations. Here’s how to build a plan that works for your business from the ground up:

1. Assess Your Requirements

Begin by aligning your inventory objectives with overall business goals—whether that’s minimizing costs, scaling operations, or boosting customer satisfaction. Next, analyze your product portfolio to understand the needs of your inventory. Group products by demand frequency, value, or turnover rate to spot trends. Finally, evaluate your current processes by collaborating with internal stakeholders and vendors to identify strengths, weaknesses, and opportunities for improvement.

2. Categorize Your Inventory

Inventory classification is essential for managing stock efficiently. Start with an ABC analysis—categorizing products into high-velocity (A), moderate-velocity (B), and low-velocity (C) tiers. From there, choose a valuation method that fits your accounting strategy: FIFO (First-In-First-Out), LIFO (Last-In-First-Out), or weighted average cost. These decisions will shape how you manage, move, and report on inventory.

3. Forecast Inventory Demand

Demand forecasting is the engine behind your inventory management plan. Use historical sales data, seasonal trends, and market conditions to determine what you’ll need, when, and where. Consider geographic demand patterns to better distribute inventory and shorten final-mile delivery times. Accurate forecasts help avoid stockouts and overstocking, and they inform SKU-level procurement strategy.

4. Set Inventory Levels

Establish key inventory thresholds: reorder points to trigger replenishment, safety stock to buffer against supply chain hiccups, and maximum stock levels to prevent overstocking. These controls help balance inventory availability with storage efficiency and working capital management.

5. Select an Inventory Management Method

Choose a methodology that fits your operation. Consider strategies like Just-in-Time (JIT) for lean inventory, Economic Order Quantity (EOQ) for optimized ordering, average costing for financial simplicity, cycle counting for regular audits, or a perpetual system for real-time accuracy. Each method has its tradeoffs—choose the appropriate method based on your supply chain complexity and business goals.

6. Use Inventory Tracking Software

Leverage inventory software with real-time tracking, barcode scanning, and robust reporting capabilities. Integration is key—connect your inventory platform with ERP, POS, and sales systems to create a single source of truth. This ensures accurate, up-to-date visibility across your entire supply chain.

7. Monitor and Optimize

Never take a set it and forget it approach to your Inventory management. Monitor KPIs like turnover ratio, stock accuracy, and carrying costs to measure performance. Conduct regular audits to catch discrepancies early and investigate root causes like shrinkage, miscounts, or data errors. Optimization should be a continuous process.

8. Develop Your Inventory Policies

Document clear rules for ordering, stocking, receiving, and handling inventory. Create training programs to ensure staff understand and follow procedures. Establish protocols and SLAs with suppliers and vendors to align expectations and minimize disruptions.

9. Plan for Contingencies

Supply chains are unpredictable—create an inventory management plan that is adaptable and resilient. Identify potential risks like supplier delays or demand surges. Create backup strategies such as alternate suppliers or emergency stock sourcing. Being proactive helps mitigate costly disruptions.

10. Review and Adjust

Inventory management is dynamic, and your plan should be too. Regularly assess its effectiveness through KPIs and stakeholder feedback. Update your strategy to reflect changes in demand, market conditions, business goals, or new technology. Continuous improvement ensures long-term success.

Hit the Ground Running With These 3 Inventory Management Practices

Ready to level up your inventory management strategy? These three best practices can help you make fast, measurable improvements. Whether you’re scaling rapidly or looking to maximize efficiency, these tactics will help you move more quickly, reduce risk, and lay the groundwork for sustainable growth.

1. Automate Inventory Tracking

Manual tracking methods leave too much room for error and delay. By automating inventory tracking with a centralized system—like an ERP or cloud-based inventory platform—you can update stock levels in real time and instantly flag overstock or stockout risks. These systems streamline your entire workflow, eliminating duplicate processes and improving data accuracy.

Automation also enables seamless omnichannel fulfillment by allowing you to monitor and reallocate inventory across warehouses, sales channels, and 3PL partners—all from one platform. With real-time visibility and fewer manual touchpoints, you’ll improve order accuracy, fulfillment speed, and inventory turnover.

2. Conduct Regular Audits

Inventory management isn’t a set-it-and-forget-it operation. Regular audits are essential for spotting discrepancies early and ensuring your data stays accurate. Rather than waiting for an annual physical count, implement cycle counting—where select SKUs are audited on a rolling basis throughout the year.

Focus on fast-moving SKUs using your ABC classification system. Auditing your A-items more frequently helps reduce shrinkage, maintain accurate records, and improve forecasting. These ongoing checks create a feedback loop that supports continuous improvement and ensures your inventory system reflects what’s actually on the shelves.

3. Scale Faster by Partnering With 3PLs

When inventory needs outpace your infrastructure, a third-party logistics (3PL) partner can help you scale without heavy investment. The right 3PL brings its own robust inventory management systems—often integrated with your existing tech stack—to offer real-time visibility and coordination.

With 3PL support, you can expand storage capacity and fulfillment capabilities quickly—especially during seasonal spikes or rapid growth periods. They also help reduce shipping costs and transit times by strategically distributing inventory across multiple fulfillment centers. That means faster delivery for your customers and fewer growing pains for your business.

Improve Inventory Management With Ware2Go

Effective inventory management is the foundation of any merchant. By creating an inventory management plan, deploying the right tools, and optimizing your inventory policies, you can reduce your inventory costs, streamline operations, and greatly improve customer satisfaction rates.

Just ensure you approach inventory management methodically and choose the right partner to guide you through the process.

For example, Ware2Go’s offers end-to-end services with plug-and-play supply chain technology. Brands can fully integrate their supply chain and sales channels with Ware2Go’s dynamic FulfillmentVu platform – empowering retailers with the ability to monitor all warehouses and inventory in real-time using one sleek dashboard.

To learn more about how Ware2Go can enable more efficient inventory management for your business, book a demo today.