Order fulfillment has the power to make or break your business. Customers want low-cost delivery options, fast.

Deliver on those customer expectations, and you’ve won customer trust and repeat business. Fail, and you’ll have to work twice as hard to win customers back.

To stay on your A-game, you’ve got to put a lot of thought into fulfilling orders and optimizing your existing processes. That’s why we’ve created this guide.

Read on to learn more about the ins and outs of order fulfillment and how it drives your business forward. We’ll also give you a breakdown of the product fulfillment process and pro tips from real business owners on optimizing your order fulfillment strategy.

What is Order Fulfillment?

Order fulfillment is the complete process of receiving, processing, and delivering customer orders.

As a business activity, order fulfillment encompasses all actions occurring after customers hit “buy” with the intent to process and complete their orders. That means the process, as a whole, includes other significant and connected operational areas such as inventory management, order processing, picking and packing, shipping, and reverse logistics (or returns management).

Because order fulfillment makes up a lion’s share of your business operations and contributes significantly to the overall customer experience, getting it right is fundamental to success.

Making the Business Run: Order Fulfillment’s Operational Impact On Your Success

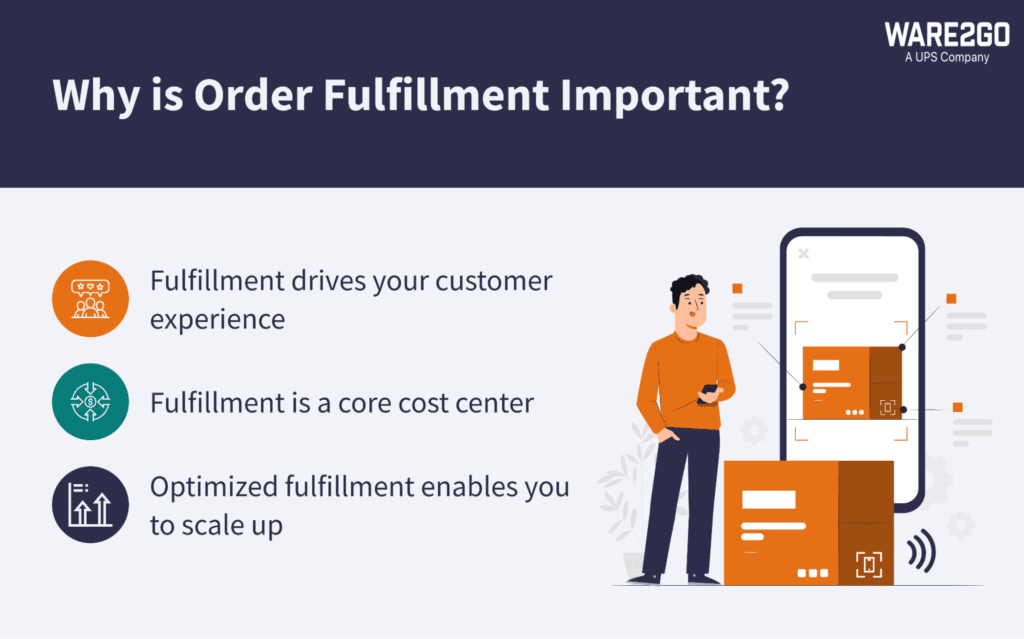

Order fulfillment isn’t just about getting your products from A to B. Depending on your operational efficiency, it can drive your customer experience and be a huge overhead.

As a result, an optimized order fulfillment strategy enables you to scale up without making a huge capital investment. We’ll explain why.

Fulfillment Drives Your Customer Experience

Order fulfillment is a key driver behind your overall customer experience.

A whopping 85% of online shoppers say they won’t order from a company twice if they have a bad shipping experience. That means you can’t afford to disappoint your customers — and maintaining an efficient, hiccup-free fulfillment process is a significant aspect of securing a positive customer experience.

Order fulfillment directly impacts:

- Speed of delivery: Shipping times are affected by how efficiently you route orders, pick and pack items, and arrange carrier pickups.

- Order accuracy: You must identify, locate, and pack each order quickly and correctly.

- Inventory visibility: Inaccurate stock levels can lead to stockouts, lost sales, and frustrated customers.

- Packaging and presentation: Packaging can change how customers perceive your brand and what you sell.

- Returns experience: Surveys show 60% of customers will ditch a brand if they’re unhappy with its returns experience.

- Personalization: Product bundling, custom packing slips, and targeted inserts based on past purchases build a stronger relationship with your customers.

Optimizing your order fulfillment workflows can drastically improve your customer experience and save you money.

Fulfillment Is a Core Cost Center

Fulfilling orders efficiently requires time and money, which are resources you’ll need to expend and will result in overhead costs. They’re a fixed expense, so they’re unavoidable — but that doesn’t mean you can’t look to reduce them to ensure your profit margins remain desirable without compromising your customer experience.

That’s why it pays to develop an optimized strategy that minimizes fulfillment costs while maximizing operational efficiency.

Order fulfillment affects:

- Warehousing costs: Efficient order fulfillment means less storage time per SKU, optimizing space, and reducing time to revenue.

- Storage costs: Inefficient fulfillment means more days in inventory storage and higher holding costs.

- Shrinkage: Quality control and tech-enabled fulfillment workflows reduce theft and misplacement.

- Picking and packaging: Inefficient fulfillment workflows mean higher labor costs, longer picking times, and more time spent on quality control.

- Carrier fees and expedited delivery: Decentralized order fulfillment reduces last-mile shipping carrier fees and minimizes the need for expensive expedited shipping costs.

- Returns shipping fees: Poor packaging or fulfillment errors can result in a higher returns rate, which often impacts your bottom line.

- Inventory loss: Optimized order fulfillment workflows prevent miscalculating inventory and misplaced returns.

By optimizing your fulfillment workflows, you’ll reduce the amount you spend on shipping orders and be able to focus on growing your business.

Optimized Fulfillment Enables You to Scale Up

Your order fulfillment strategy doesn’t just play a critical role in your ability to deliver for customers. It also dictates how well you can scale up as your business grows.

That’s why fast-growing brands need to consider a flexible fulfillment model. The rapid pace at which order volume changes for these brands demands greater agility when navigating high-volume sales and order periods, which is what a flexible fulfillment model aims to provide. Its terms also equip a business in the high-growth phase to stay “light” and commitment-free.

By partnering with a tech-enabled third-party logistics (3PL) partner like Ware2Go, you can build your fulfillment network based on your business’s needs. As customer demand grows or shifts seasonally, you can leverage existing fulfillment facilities, software, and teams without compromising speed, accuracy, or cost efficiency.

But if your brand crawls along using siloed software systems and costly, centralized warehouses, your order fulfillment processes could hurt your chances of generating growth.

How Does Order Fulfillment Work?

We’ve already established that order fulfillment is a major component of your business operations.

However, the easiest way to manage the fulfillment process is to break it down into four core functions: order receiving, order processing, shipping, last-mile delivery, and returns management.

Step 1. Order Receiving

This is where it all starts. After your customer makes a purchase, you’ve got to receive the new order and orchestrate how and where it’s fulfilled. When done manually, this process can be incredibly time-consuming and complex, which is why automation is key.

By automatically routing orders as they’re received, you can ensure each order is sent to the appropriate warehouse based on end customer location and inventory availability. That requires an inventory management system to ensure real-time visibility over multiple fulfillment centers.

More importantly, you need to integrate your inventory management software with your order fulfillment software. Seamlessly connecting these systems positions you well to avoid stockouts and overstocks.

Step 2. Order Processing

After routing an order to the optimal warehouse location, it’s time to process it. That means picking, packing, and labeling each order so it’s ready to get shipped.

Technology like a warehouse management system (WMS) will reduce errors and improve speed. A WMS uses SKU velocity and SKU dimensions to determine the most efficient way to pick, package, and label orders.

In addition to your tech stack, same-day fulfillment is an effective lever your brand can pull to decrease the time between purchase and delivery. Quick and efficient processing workflows mean your orders get out the door faster. That’s what enables same-day shipping.

Want to see how it’s done? Check out these pro tips:

Step 3. Shipping and Last-mile Delivery

Once an order is processed, last-mile logistics is a package’s final trip in the logistics process. It sees each package from the fulfillment center, right to the consumer’s doorstep or mailbox. This is also a very public-facing component of your brand image.

That’s why choosing a logistics partner or carriers capable of supporting dynamic routing strategies is important to ensure a fast and reliable delivery process. After all, what’s the point in working hard to achieve same-day fulfillment when your carrying partner is prone to shipping delays?

That’s why Ware2Go leverages tools like last-mile delivery tracking and predictive analytics. These enable our teams to automatically reroute orders to the next-closest warehouse in the case of inclement weather. Meanwhile, our nationwide network and close partnership with UPS support reliable 1-2-day last-mile delivery.

Step 4. Returns Management

The average eCommerce business return rate is 26.4%, and if your returns management system isn’t particularly efficient, returns could eat into your bottom line.

Returns management can be fairly complex, as it involves several workflows. This includes:

- Request to return and reverse logistics

- Receipt of goods

- Inspection

- Processing

- Restocking, refurbishment, or disposal

- Refund or replacement

By integrating all of your systems under one tech stack, you should be able to get a centralized view of your returns management and streamline your reverse logistics processes. As a result, you’ll be able to simultaneously minimize your losses and keep your customer satisfaction levels high.

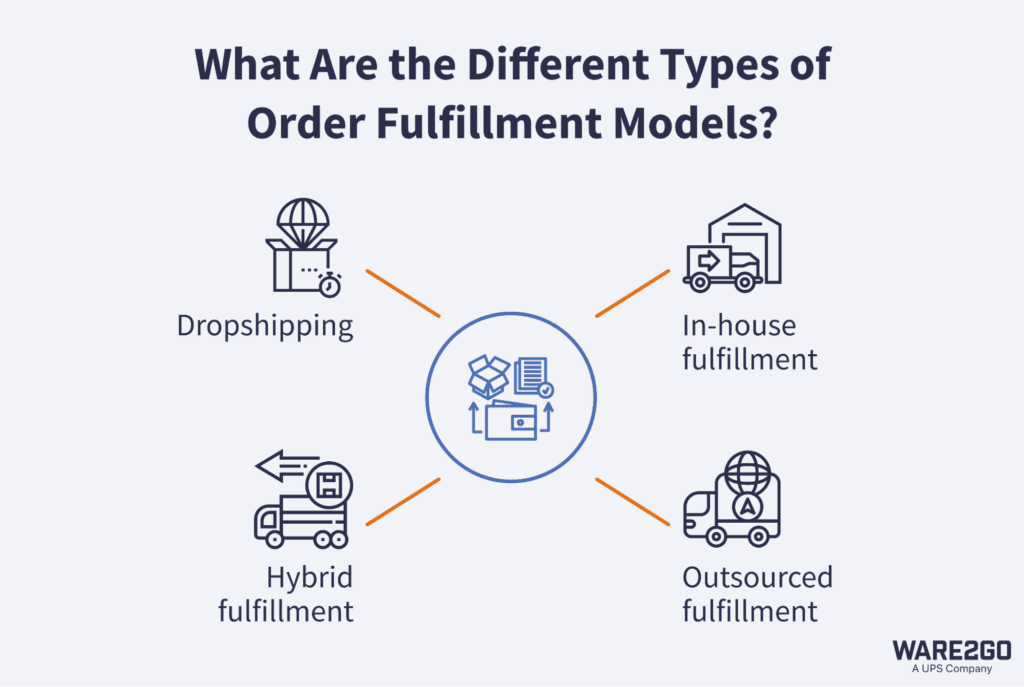

What Are the Different Models You Can Use for Product Fulfillment?

Order fulfillment isn’t just complicated because there are so many functions involved. It can also be complicated because brands use several different fulfillment models to facilitate it.

Let’s take a quick look at common types of fulfillment:

Option 1: In-house Fulfillment

An in-house order fulfillment strategy lets your brand control each fulfillment function. The primary benefits here are that you have:

- Full control over your order fulfillment strategy

- Full ability to customize your fulfillment workflows

- Oversight to maintain brand consistency

- The ability to make decisions fast

But there are some major in-house fulfillment challenges, too. In-house order fulfillment often means:

- High operational costs

- Major investment

- Scalability issues when dealing with surges in demand or shifts in key customer locations

- No access to expertise for complex challenges

That’s why so many brands choose to outsource fulfillment.

Option 2: Outsourced Fulfillment

As we’ve already pointed out, the order fulfillment process can be incredibly complex. That’s where a 3PL partner can make life a whole lot easier.

By outsourcing your order fulfillment to a 3PL expert, you can leverage direct integrations to connect each fulfillment function instantly. The only real challenge in outsourcing your fulfillment process is that you’re limited to the existing capabilities of your partner’s network and technology.

That’s why you must select a tech-enabled 3PL that offers the capability and flexibility your business model requires.

For example, Ware2Go’s FulfillmentVu platform integrates with your existing tech stack and offers consistent insights into your customer experience and branding.

Meanwhile, scaling up (or back) is easy and requires no capital investment. You can scale instantly and create a bespoke network using Ware2Go’s nationwide network of 15+ warehouses. That lets you proactively manage demand with seasonal fulfillment, marketplace fulfillment, and end-to-end freight capability.

Option 3: Dropshipping

Dropshipping is an order fulfillment method where a seller doesn’t keep products in stock. Instead, they buy inventory from a third party, who ships it directly to the customer base on their behalf.

The benefits of using dropshipping are that it doesn’t require a big upfront investment, the overheads are low, and you’re not taking on a lot of risk because you don’t own the inventory you’re selling.

But that’s also a drawback for many brands. You’ve limited control over product quality and shipping times, you’ll be dealing with a lower profit margin, and your shipping network often ends up growing arms and legs quickly.

Option 4: Hybrid Fulfillment

Hybrid fulfillment sees brands combine in-house fulfillment, outsourced fulfillment, and dropshipping elements to create a combined strategy.

A hybrid model mitigates risk because its fulfillment chains are spread across multiple networks and providers. This also makes it easier to scale up and pivot in response to demand or supply chain disruptions.

The optimal approach here is generally to hand over the “squeaky wheels” that are more difficult to manage internally to a 3PL like Ware2Go. That might mean outsourcing your more complicated SKUs, bulky items, or marketplace fulfillment to ensure strict requirements are met, freeing up your time to focus on building core business activities.

On the Road to Optimizing a More Efficient Order Fulfillment Strategy

Regardless of the fulfillment methods you decide to use as part of your order fulfillment strategy, it’s important to consider what you’re doing to streamline your operations.

To help you get started, we’ve broken the optimization process down into five crucial steps:

1. Assess Current Fulfillment Strategy

First things first: you’ve got to take stock of your existing order fulfillment processes. This will enable you to identify performance levels and spot potential pain points and bottlenecks holding you back.

That’s exactly what Austin Bazaar did.

After conducting a strategy assessment, the long-time Amazon seller realized that Fulfillment by Amazon (FBA) didn’t enable them to scale as a multi-channel business. The hidden fees and inventory requirements were limiting the control of their sales strategy.

This pushed the team to partner with Ware2Go, which enabled them to expand their 2-day delivery footprint, self-fulfill their Amazon orders, and maintain Prime status through Seller Fulfilled Prime (SFP).

“When the cost and complexity of FBA increased, we turned to Seller Fulfilled Prime—especially for our Oversized and Extra Large products,” explains Suman Singh, CEO of Austin Bazaar

“Doing SFP with the help of Ware2Go is how we made Amazon work for Austin Bazaar.”

2. Map Out Your Existing Fulfillment Network

Next, you’ve got to map out your existing fulfillment network. Cross-reference that against customer location to identify how relocating warehousing facilities could be optimized based on customer purchase behavior.

For best practice lessons, look at 100 Thieves and their new energy drink, Juvee.

Although they’re based in LA, 60% of 100 Thieves’ customers are on the East Coast, which proved a logistical challenge for the gaming and lifestyle brand. That’s why they decided to build their fulfillment network with Ware2Go.

“Ware2Go gave us the flexibility to announce a brand-new product to our over one million fans with full confidence that we could launch and deliver smoothly regardless of how fast orders came in,” says Sam Keene, General Manager.

By distributing inventory across three Ware2Go warehouses, 100 Thieves found they could deliver to 95% of their customers with 1- to 2-day ground shipping.

3. Automate by Integrating Technology

Effective order fulfillment needs integration if it’s going to be as efficient for your internal operations as you intend. Unifying your existing order management, inventory management, and fulfillment systems will enable inventory visibility and increase the opportunity for automation.

That’s how O2 Recovery streamlined its order fulfillment operations.

Ware2Go’s seamless integration with O2 Recovery’s existing Shopify store enabled the brand to align with a responsive fulfillment system.

The interconnected communications and workflows enabled them to replenish orders to their gym partners within 1-2 days.

4. Optimize Packaging

Assessing and identifying areas where product packaging can be optimized is critical. This can be a tricky balancing act, as you need to align cost savings with product protection, brand integrity, and sustainability.

For a brand like Yelle Skin Care, packaging materials are particularly essential.

“We are a company that believes in representation and presentation,” explains Yandy Smith-Harris, CEO.

“For me to let go of the unboxing experience, it had to be with a company I could trust and believed could really capture the essence of what my brand represents.”

That’s why Yelle prioritized maintaining brand integrity and vision when partnering with a 3PL — and it’s what led them to Ware2Go.

Yelle’s unboxing experience includes custom-printed boxes, shredded paper, custom marketing inserts, and pack-out SOPs to ensure safety in transit. Not every 3PL is equipped to handle an experience like that, so choosing partners with both the expertise and the operational technology to support these types of details can set you apart from your competition.

5. Create a Proactive Returns Management Strategy

To optimize your returns management strategy, you’ll need to take a few big steps. First, decide whether you’ll offer in-store returns, mail-in returns, both, or neither. Then, develop a return window (usually between 30 and 60 days) and decide whether you’ll cover the cost of return shipping.

Reverse logistics can be complicated and costly, and a 3PL partner like Ware2Go can offer some much-needed support.

That journey starts with quality control. On receipt, returned products undergo a thorough inspection to determine whether they’re eligible for resale. Only undamaged, sellable products re-enter your inventory.

Next comes restocking, refunds or vendor credits, and recycling or disposing of products that can’t be resold or repaired responsibly. Environmental sustainability and regulatory compliance come into play here, so there’s a lot to consider in this area.

Order Fulfillment FAQs

Still have questions about order fulfillment and what it means for your brand? We’ve got all your bases covered:

What Does Order Fulfilled Mean?

When an order’s status is fulfilled, all its items have been successfully shipped to your customer.

How Do You Fulfill An Order?

Your business must receive, process, pack, and ship an order to fulfill it.

How Can You Reduce Delivery Times When Fulfilling Orders?

Efficient inventory management, route optimization, automated shipping processes, and third-party fulfillment can reduce delivery times.

Let’s Start Optimizing Your Order Fulfillment

No two businesses are 100% alike, so every brand’s perfect order fulfillment strategy looks different. You’ve got to carefully assess your capability, requirements, and growth strategy when putting together a comprehensive order fulfillment strategy.

And if you need support, Ware2Go can help.

By partnering with Ware2Go, you’ll gain access to on‑demand fulfillment and a nationwide transportation network, which enables you to optimize your warehousing, streamline processes, and win over customers with 1–2 day shipping.