As every online retailer knows, we live in a two-day delivery world where customers expect both speed and reliability. Yet even the most successful brands face inventory challenges, and sometimes stockouts are unavoidable. This is why businesses turn to backorders to strategically maintain customer satisfaction and revenue growth.

Backorder management has evolved from a last-resort tactic to a strategic necessity for modern fulfillment operations. With supply chain issues becoming more frequent due to labor strikes, geopolitical tensions, and climate events, businesses need sophisticated approaches to maintain revenue flow during stockouts.

By allowing customers to purchase temporarily out-of-stock items, companies can preserve customer relationships while gaining valuable demand data.

However, successful backorder management requires more than simply accepting orders for out-of-stock items. It demands sophisticated inventory tracking, transparent customer communication, and seamless integration with your fulfillment operations.

When implemented correctly, a backorder strategy can transform potential lost sales into future revenue while enhancing customer loyalty.

In this comprehensive guide, we’ll explore the essential elements of effective backorder management, from technology requirements to customer communication strategies, helping you build a resilient fulfillment operation that turns stockouts into opportunities.

Understanding Backorders in Modern Fulfillment

Managing inventory is a balancing act, and even the best-run businesses face times when demand outpaces supply. That’s where backorders come into play. Backorders aren’t just a way to keep sales alive during stockouts — they’re an opportunity to show customers you value their business, even when items aren’t immediately available.

Let’s explore what makes backorders a smart strategy, what causes them, and how they’ve evolved into a key part of modern fulfillment.

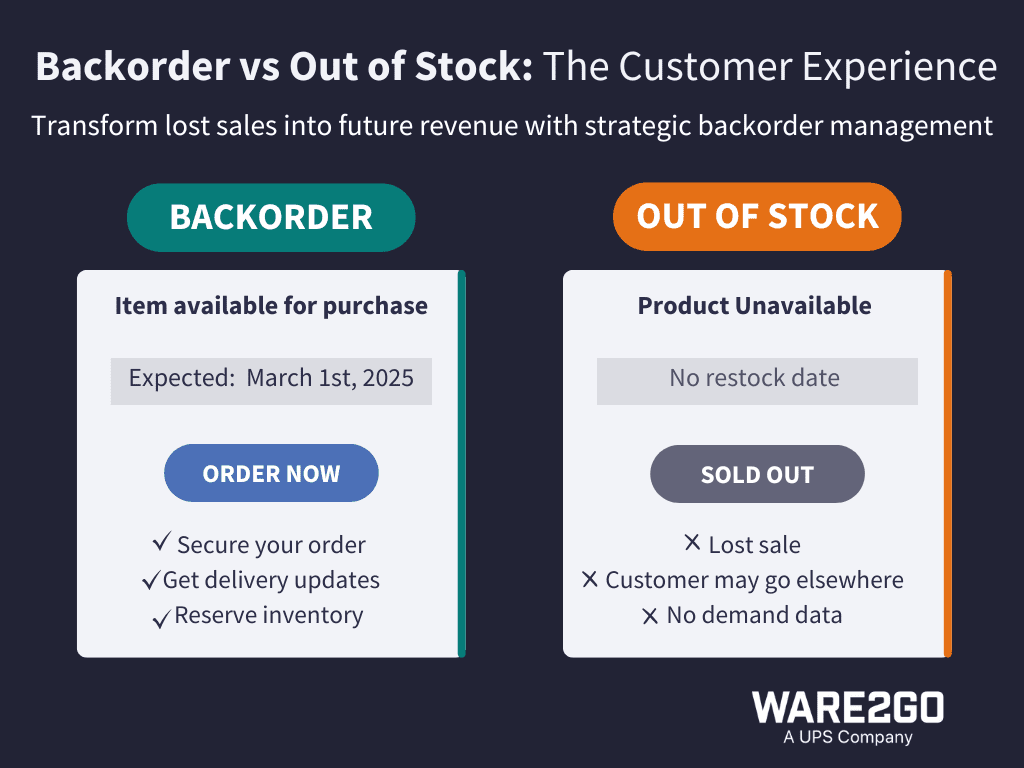

Backorders vs. Out of Stock

It’s easy to confuse backorders with being “out of stock,” but they’re not the same. Backorders mean customers can still purchase an item, even if it’s temporarily unavailable, with the promise that it’ll ship as soon as it’s back in stock. Being out of stock, on the other hand, means sales stop entirely — and so does the chance to keep that customer engaged.

Imagine you’re shopping for a popular limited-edition jacket. If it’s a backordered item, you can still place your order and feel confident you’ll get it later. If it’s marked “out of stock,” you’re likely to move on to another store and possibly another brand. Items on backorder keep the door open for sales while also maintaining trust with customers.

Backordered products also play a big role in keeping your business running smoothly:

- They keep cash flowing. Instead of losing revenue during a stockout, you’re still making sales.

- They help with planning. Backorder data gives you a clearer picture of demand so that you can adjust future orders accordingly.

- They reduce overstocking. Knowing you can rely on backordered items means you don’t have to keep excess inventory or safety stock on hand, freeing up warehouse space.

Of course, customers’ willingness to wait depends on how well you communicate. If they know when to expect their item and feel updated along the way, they’re more likely to stay loyal. Transparency turns backordered products into an opportunity to strengthen your relationship with them.

What Causes Backorders?

Backorders can happen for all kinds of reasons. Some are external factors that are hard to control, while others come down to internal processes. Let’s break it down:

- Supply Chain Challenges – Global supply chains have been hit hard by issues like cyberattacks (which cost businesses $12.5 billion in 2023, according to KPMG), climate events (such as hurricanes and wildfires), and geopolitical tensions like the Red Sea crisis. These disruptions slow down production and shipping, making backorders unavoidable.

- Forecasting Mistakes – Predicting demand is tricky. Underestimating how much inventory you’ll need during a busy season can quickly lead to stockouts and backorders. However, supply chain tools like Ware2Go’s demand forecasting tool can minimize errors that lead to backorders.

- Supplier Delays – If your suppliers take longer than expected to deliver, your shelves could run empty before new stock arrives.

- Sudden Demand Spikes – Viral trends or unexpected surges — like a product going viral on social media — can create unusual demand that far exceeds your stock levels.

While you can’t control every factor, improving inventory management and supply chain flexibility can help reduce the frequency of backorders.

The Evolution of Backorder Management

Backorders aren’t a new concept — they’ve been around for decades. Traditional retail stores and pharmacies have long relied on backorders to keep customers happy when items aren’t immediately available. But today, technology has taken backorder management to a whole new level.

Here are a few ways businesses are modernizing the process:

- AI Forecasting – Artificial intelligence helps predict demand more accurately, reducing the risk of stockouts.

- Real-Time Tracking – Advanced systems give you instant visibility into your inventory and supply chain so that you can manage backorders proactively.

- Automated Updates – Technology makes it easy to keep customers informed with notifications about when their items will ship.

Recent supply chain challenges have also driven innovation:

- Flexibility in Shipping – Rerouting shipments and adjusting delivery methods help businesses stay agile.

- Nearshoring – Partnering with suppliers closer to home reduces the risk of global disruptions.

- Stronger Risk Management – Diversifying suppliers and building contingency plans make businesses more resilient.

In the end, backorders aren’t just about managing shortages — they’re about building trust and staying adaptable. When done right, they can turn a challenge into an opportunity to strengthen your customer relationships and grow your business.

The Pros and Cons of Backorder Implementation

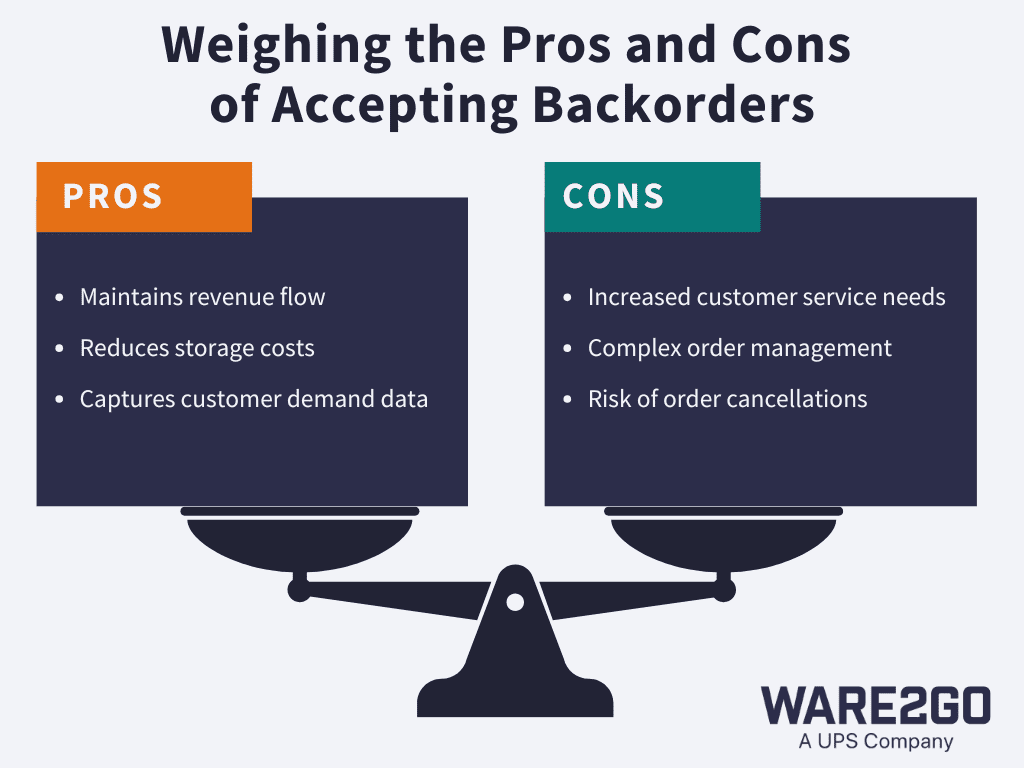

Backorders can be a powerful tool in your fulfillment strategy, but like any approach, they come with both advantages and challenges. Understanding the trade-offs helps you maximize their benefits while minimizing potential downsides.

The Pros: Financial Advantages

One of the biggest benefits of backorders is maintaining cash flow during stockouts. Instead of losing sales when inventory runs low, you continue generating revenue, which you can reinvest to support other areas of your business. This steady cash flow is especially critical for businesses with seasonal peaks or high-demand products.

Backorders also help optimize inventory carrying costs. With the ability to fulfill demand even when stock runs dry, you can reduce the need for excessive safety stock, freeing up warehouse space and lowering holding costs. This leaner approach means you’re not tying up capital in inventory that might sit unsold for months.

Additionally, backorders can finance future inventory purchases. The revenue generated from backorders allows you to restock popular products without overextending your budget. It’s a smart way to align cash inflow with outflow while meeting customer needs.

The Cons: Customer Experience Impact

While backorders can keep your business financially healthy, they can also come with challenges for the customer experience. Nobody likes waiting longer than expected for their purchase, so maintaining customer satisfaction during backorder periods requires a thoughtful approach.

The key is transparent communication. Be upfront about estimated delivery timelines and provide regular updates if those timelines change. Automated notifications can help keep customers in the loop without extra effort on your part.

To turn backorders into a loyalty-building opportunity, focus on creating a positive customer experience. Offer small perks, like discounts on future purchases or free shipping, to show appreciation for their patience. These gestures demonstrate that you value their time and business.

By balancing financial advantages with a customer-first mindset, backorders can evolve from a logistical challenge into a tool for growth, ensuring both your bottom line and your relationships stay strong.

How to Navigate Backorders for Your Shop

Managing backorders effectively requires a combination of the right tools, data insights, and proactive strategies. With the right systems in place, backorders can be an opportunity to strengthen your operations and build trust with your customers.

Essential Systems for Backorder Management

To successfully manage backorders, you need a robust inventory management system (IMS). Key features include real-time tracking, centralized visibility across warehouses, and automated stock level alerts. These capabilities help you stay ahead of inventory shortages and improve order accuracy.

Integration with your order management system (OMS) is equally important. When these systems work together, you can automatically update product availability across all sales channels, ensuring customers are informed about backorder timelines at the moment of purchase.

Automation is another game-changer. Automating backorder processes — like notifying customers about estimated delivery dates or reordering stock from suppliers — saves time and reduces errors. Advanced systems even allow for automatic prioritization of backorders based on factors like order volume or customer value.

Data Analytics and Forecasting

Data is your secret weapon for backorder management. Start by analyzing historical sales trends to predict when certain products are most likely to experience high demand. This helps you plan inventory more effectively and reduce the risk of stockouts.

Tracking key metrics, such as backorder rates, average fulfillment time, and customer satisfaction scores, gives you a clear picture of your performance. These insights allow you to identify areas for improvement and adjust your strategies in real time.

Predictive analytics takes it a step further, helping you anticipate future demand spikes and potential disruptions. With AI-driven tools, you can optimize your supply chain, proactively address inventory gaps, and ensure smoother backorder management.

With the right systems and insights, navigating backorders becomes not just manageable but an opportunity for operational excellence.

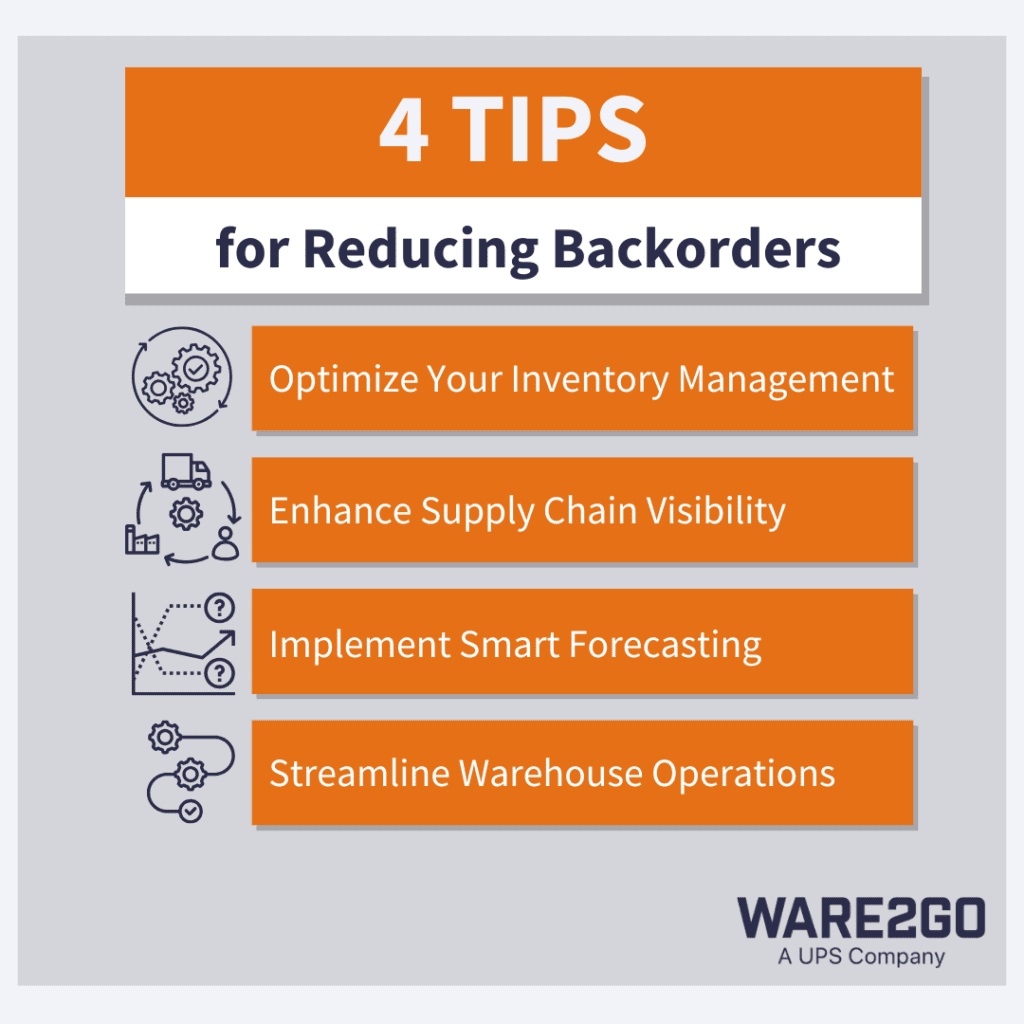

4 Ways to Reduce Excessive Backorders for Your Business

Excessive backorders can strain customer relationships and disrupt operations, but with the right strategies, you can minimize their occurrence. Here are 4 practical steps to reduce backorders and keep your business running smoothly.

1) Optimize Your Inventory Management

Accurate inventory management starts with setting proper reorder points. Use historical sales data, demand trends, and supplier lead times to calculate when to restock before hitting critically low levels. This data-driven approach ensures your shelves are ready when demand spikes.

Maintaining the right safety stock is equally important. While keeping extra stock can prevent stockouts, too much inventory ties up capital and storage space. Aim for balance by monitoring sales patterns and regularly reassessing safety stock needs.

Real-time inventory tracking is a game-changer. With visibility across multiple warehouses, you can avoid overselling and route orders efficiently. Centralized systems that sync with your sales channels are essential for ensuring inventory accuracy.

2) Enhance Supply Chain Visibility

A transparent supply chain helps prevent backorder surprises. Start by strengthening communication with suppliers. Regular updates on lead times, potential delays, and production schedules keep you informed and prepared.

Diversifying your supplier network adds another layer of protection. Relying on a single supplier increases risk; working with multiple vendors ensures flexibility if one experiences disruptions.

Leverage networks like UPS’s for better visibility into shipping timelines and logistics. Advanced tools from trusted providers can offer insights into potential bottlenecks, giving you time to adjust.

3) Implement Smart Forecasting

Forecasting accurately is key to avoiding inventory shortages. Use historical sales data and seasonal trends to anticipate demand spikes. For example, plan ahead for holiday shopping or product launches based on past performance.

AI and machine learning take inventory forecasting to the next level. These tools analyze complex data patterns to predict demand more precisely, helping you make informed purchasing decisions.

Market conditions can change quickly, so adjust forecasts regularly. Monitor trends like economic shifts, competitor activity, or changes in consumer behavior to stay ahead.

4) Streamline Warehouse Operations

Efficient warehouses reduce delays. Cross-docking — where inbound shipments are quickly routed to outbound trucks — speeds up fulfillment, minimizing backorder delays.

Organize your warehouse layout to improve pick-and-pack efficiency. Group high-demand items in accessible areas to reduce processing time.

Lastly, optimize your pick, pack, and ship processes with automation and clear workflows. Faster fulfillment means backorders are resolved quickly, keeping customers happy.

Strike the Right Backorder Balance with Ware2Go

Successful backorder management is a critical capability for modern fulfillment operations. By implementing robust systems, maintaining transparent communication, and leveraging technology effectively, you can transform stockouts from potential losses into opportunities for future revenue.

The key lies in viewing backorders not as a necessary evil but as a strategic tool for inventory and customer relationship management. As supply chains continue to face disruptions, mastering backorder management becomes increasingly crucial for sustainable business growth.

To learn more about how Ware2Go can help you with backorder management, talk to our team today.