Solutions for managing inventory aren’t a “one-size-fits-all” situation. Rather, it’s a strategic choice that can make or break your bottom line—and you can use it to gain control and maintain a significant operational edge.

For startups and small businesses, a periodic inventory system is a straightforward and budget-friendly way to track stock without constant oversight.

This method simplifies operations and eliminates the need for constant monitoring, making it a popular choice for businesses with limited resources. But is it the right choice for you?

If you’re ready to take your operations to the next level, download Ware2Go’s eBook on warehousing and fulfillment for expert insights to optimize your supply chain.

In this article, we’ll explore how a periodic inventory system works, the pros and cons, and whether it’s the right move for your inventory success story.

What is a Periodic Inventory System?

A periodic inventory system is an inventory accounting method that updates stock levels at specific intervals—weekly, monthly, or seasonally—rather than in real-time. Businesses using this system rely on physical counts to calculate inventory at the end of each period, recording the cost of goods sold (COGS) only after inventory counts. This contrasts with the perpetual inventory method, which tracks inventory in real-time using warehousing and inventory management technology and automation.

The periodic inventory method is most popular among small businesses and companies with straightforward supply chains, where inventory volume and turnover are relatively manageable. Seasonal businesses, such as holiday retail shops or event-based sellers, also find this method useful.

Importance of Inventory Management

Accurate inventory management plays a critical role in optimizing business operations by reducing waste, preventing costly stockouts, and improving cash flow. However, 43% of small businesses admit that they don’t track inventory.

Additionally, proper inventory management is key to meeting consumer expectations for fast delivery without inflating operational costs. According to a survey by WareGo, a UPS Company, 45% of consumers expect 2-day delivery on all online orders. That can be a tall order for some fast-growing brands.

As Ware2Go’s supply chain expert explains in the video below, knowing the “what, how much, and where” of inventory management enables you to deliver to all of your customers within 2 days without diminishing margins.

How Does a Periodic Inventory System Work?

At the most basic level, a periodic inventory system works by updating inventory levels at scheduled intervals through physical counts as opposed to tracking stock in real-time.

Examples of a Periodic Inventory System

In a periodic inventory system, businesses perform scheduled physical counts—daily, monthly, or at the end of a season. For example:

- Retail stores might conduct monthly counts after closing to adjust inventory records.

- Seasonal businesses with high turnover during specific periods—such as holiday shops—often count inventory on a quarterly basis.

This system is well-suited for industries with slower-moving inventory or predictable stock cycles, such as seasonal goods or luxury brands.

Calculating Periodic Inventory

In a periodic inventory system, calculating the cost of goods sold (COGS) is straightforward:

Periodic Inventory System Formula:

COGS = Beginning Inventory + Purchases – Ending Inventory

Example:

Let’s say your business starts the month with $10,000 in inventory. You purchase an additional $5,000 in goods and conduct a physical count at month’s end, showing $4,000 in remaining inventory. Your COGS for the month would be:

$10,000 + $5,000 – $4,000 = $11,000

Many businesses use templates and accounting tools to streamline this process. Journal entries for each period record the beginning and ending inventory, purchases, and adjustments.

What’s the Difference Between the Periodic and Perpetual Inventory Systems?

Perpetual and periodic inventory systems are different approaches to stock management. Periodic systems make use of physical inventory counts at set times. Therefore data is only accurate after these counts. Setup costs are lower, but they require more manual work, resulting in increased labor costs. They are suitable for businesses with limited inventory.

Perpetual systems, on the other hand, constantly update inventory levels, resulting in real-time data. Ongoing tracking enables greater inventory control and more strategic decision-making. Larger operations or those with complex product catalogs often require the real-time accuracy of a perpetual system.

| Periodic Inventory System | Perpetual Inventory System | |

| Frequency of Updates | At specific intervals | Continuously |

| Inventory Data | Accurate only after physical count | Real time |

| Implementation Cost | Typically less expensive | Generally more expensive |

| Labor Requirements | More manual labor for counts | Less manual labor for counts |

| Inventory Control | Limited | Better |

| Decision-Making Capabilities | Limited | Enhanced due to real-time data |

| Suitability | Small businesses with limited inventory | Larger operations or complex inventory needs |

What are the Advantages and Disadvantages of a Periodic Inventory System?

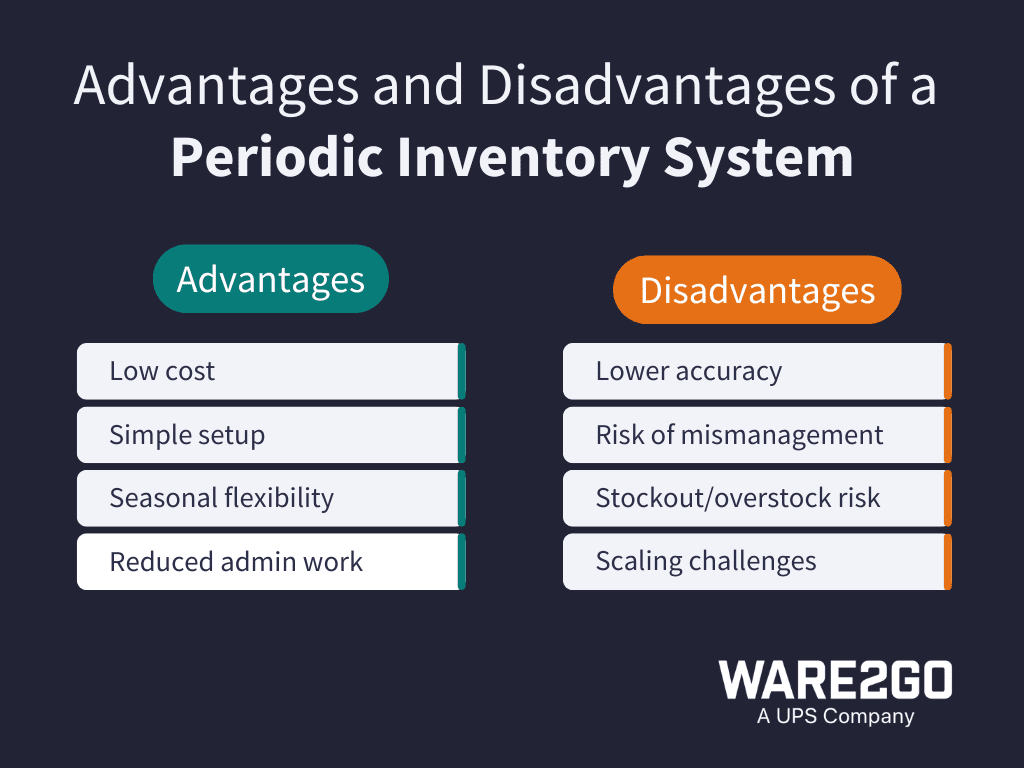

A periodic inventory system offers several advantages for businesses with seasonal sales cycles. Its low cost, ease of use, and flexibility make it an attractive option for small businesses and startups managing inventory without sophisticated technology.

Advantages of a Periodic Inventory System

A periodic inventory system offers key advantages for businesses seeking a cost-effective and straightforward approach to managing inventory. Advantages include:

Lower cost: Manual physical inventory counts require minimal technology investment, which frees up more capital to invest in other areas of the business.

Simplicity: For small businesses or startups, the simplicity of a perpetual inventory system enables lean teams to focus on core competencies.

Flexibility: With a periodic inventory system, you choose when to perform physical inventory counts. You can put more focus on inventory management during the most critical times of the year for your business.

Reduced administrative burden: With fewer daily updates, your team will spend less time on inventory management.

Disadvantages of a Periodic Inventory System

While simple and affordable, a periodic inventory system has some notable drawbacks, especially for fast-growing businesses. The disadvantages include:

Less accuracy: The gaps of time between stock counts increase the possibility of loss and damage that goes unnoticed, resulting in more discrepancies.

Stock mismanagement: There is a greater potential for stockouts or overstocking with a periodic inventory system. This leads to a higher potential for excess inventory that elevates operational costs and diminishes margins.

Limited scalability: Manual stock counts are time-consuming and more prone to errors at scale. They are therefore not suitable for fast-growing or high-volume businesses.

FAQs

In this FAQ section, we address common questions about perpetual inventory systems, helping you decide if this real-time tracking method is the right fit for your business.

Is a Periodic Inventory System Right for My Business?

This system is well-suited for:

- Small businesses with manageable inventory volumes.

- Startups just beginning to track inventory.

- Seasonal businesses with predictable inventory cycles.

How Often Should I Conduct Stock Counts in a Periodic Inventory System?

The frequency depends on your business size and turnover rate:

- Small businesses: Monthly or quarterly counts.

- Retail businesses: Weekly or monthly counts.

- Seasonal businesses: Post-season counts.

Can I Transition From a Periodic to a Perpetual Inventory System?

Yes, transitioning is possible and advisable as your business grows. Start by investing in inventory management software, train your staff, and gradually phase out manual counts.

Choosing the Right Inventory System For Your Business

Choosing the right inventory system is a game-changer for your business. The periodic inventory system is a simple, cost-effective solution perfect for many small and seasonal businesses. But if scaling is on your horizon sooner rather than later, you’ll need to weigh the trade-offs.

Every business is unique, and finding an inventory system that fits like a glove will set you up for success.

Need expert guidance? Reach out to Ware2Go to explore tailored solutions that simplify inventory management and fulfillment. Let us help you streamline your supply chain and deliver what your customers want faster.