Nearly half of businesses say that managing inventory is their biggest hurdle. Getting better at managing your warehousing and inventory is a big deal and will positively impact your sales.

Markets change fast, and keeping up with the latest developments is essential if you’re going to stay ahead of the curve. Knowing how to handle warehouse challenges and use the newest tech helps keep things running and supports steady growth.

We’ve compiled a guide that discusses common problems and useful tips with new trends to help you work smarter and grow your business faster.

Understanding Inventory Management and Warehouse Management

Warehouse management and inventory management are both key parts of the supply chain, but they do different things. We need both to work well together to keep operations running smoothly. Let’s break down what each one does, how they’re different, and why both are important for getting products to customers efficiently.

What is Inventory Management?

Inventory management is all about holding the right amount of inventory to ensure we can meet customer orders without having cash tied up in stock.

It involves tracking inventory from time of purchase to sale. Good inventory management means we turn inventory often and avoid getting stuck with items we can’t sell. It helps us save money and keeps cash flowing in our business. It also makes our customers happy because they get what they want without delays.

What is Warehouse Management?

Warehouse management includes the physical storage of goods — plus managing warehouse staff and equipment to make the receipt, storage, and dispatch of goods possible. We want to ensure the warehouse team knows what to do, keeps track of all our goods, and gets all items picked and packed efficiently.

The main goals of warehouse management are to:

- Reduce errors.

- Speed order processing timesup how fast we get orders out.

- Keep the warehouse running smoothly.

Effective warehouse management optimizes storage, staff, and operations, focusing on reducing errors, accelerating order processing, and ensuring smooth workflows. This approach enhances productivity and operational efficiency in the warehouse.

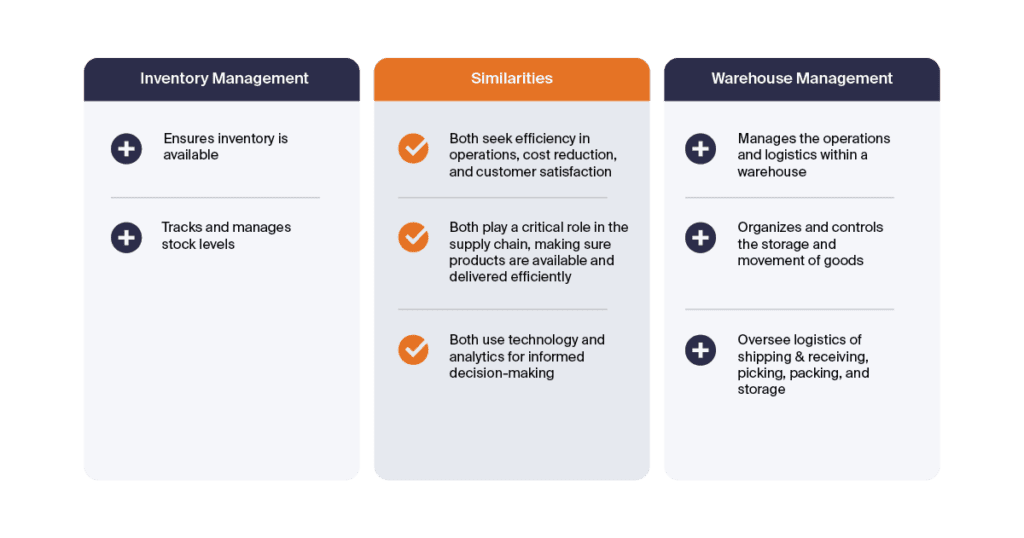

Key Distinctions Between Warehousing and Inventory Management

- Inventory management is about the “what” and “how much”. It zeroes in on tracking stock levels and forecasting demand to ensure products are available when needed.

- Warehouse management, on the other hand, focuses on the “where” and “how”. Its focus is the logistics of order fulfillment, shipping, and the efficient organization of goods within a warehouse.

This distinction is critical, considering 34% of businesses report challenges with unavailable products and delayed shipments due to inventory and warehouse management inefficiencies. Confusion or inefficiencies in either part of your fulfillment processes can lead to product unavailability and shipment delays, directly impacting business performance.

Understanding these two critical aspects of fulfillment is the first step toward addressing challenges and improving supply chain operations for increased efficiency and higher customer satisfaction.

Similarities and Differences Between Inventory and Warehouse Management

At the core of warehousing and inventory management are some common goals:

- Making day-to-day business operations more efficient.

- Cost-effective management of inventory.

- Having enough product available for customers while minimizing inventory carry costs.

Both disciplines aim to streamline operations, ensuring products are readily available for customers while minimizing working capital tied up in stock. By reducing stockouts and overstocked items, you can lower the overall cost of inventory.

Inventory management focuses on maintaining optimal inventory levels to ensure stock is aligned with demand forecasts.

This includes:

- Order management.

- Stock replenishment.

- Inventory turnover analysis.

On the other hand, the essence of warehouse management lies in operational activities within the warehouse premises and focuses on how to manage warehouse inventory. These include things like:

- The allocation of storage space.

- Goods handling.

- Optimization of picking and packing processes.

You need to look at inventory management and warehousing functions together if you’re going to create an overall effective strategy for your business. You need to make sure that the more theoretical inventory management plans will work within the real-world conditions of the warehouse.

The Business Impact of Effective Inventory and Warehouse Management

Keeping warehouse and inventory in check is about more than just storage. This involves making customers happy and getting orders out the door quickly.

When businesses match what they have in stock with what their customers want, they can send out orders faster. This keeps customers happy, especially in today’s world where no one likes to wait.

Even a small delay can upset a customer and lead to missed sales.

Also, being smart about managing inventory and warehouses helps to save money. You avoid having too much or too little stock, both of which can cost you unnecessarily by tying up capital or leading to lost sales opportunities. By getting things just right, you spend less on storing goods and running your warehouse, which means more profit for your business.

Scalability and ability to respond to market changes are heavily influenced by how well you manage your warehouse inventory. Efficient workflows let you respond faster to market demands, allowing businesses to scale operations up or down without incurring unnecessary extra costs.

This flexibility is important for sustaining growth and remaining competitive in changing market conditions.

How to Manage Warehouse Inventory in Modern Times: Trends in Logistics

Adopting modern technology in warehousing and inventory management systems can offer a promising increase to our return on investment (ROI).

Automated systems, warehouse management software, and AI-driven tools:

- Improve accuracy.

- Reduce manual labor costs and human error.

- Enhance inventory forecasting.

- Improve decision-making through better data analytics.

One big emerging trend in the logistics sector is co-warehousing. By enabling third-party logistics (3PLs) and warehouses to share space and resources, co-warehousing maximizes brands’ use of space and yields cost savings. This collaborative approach to warehousing reflects a broader shift towards more efficient supply chain solutions.

Ware2Go’s Core Processes and Functions of Inventory Management and Warehousing

Learning to manage your warehouse inventory is a complex task. There are several important processes required to be efficient and effective. Understanding these warehouse processes is essential for any business looking to improve its logistics operations.

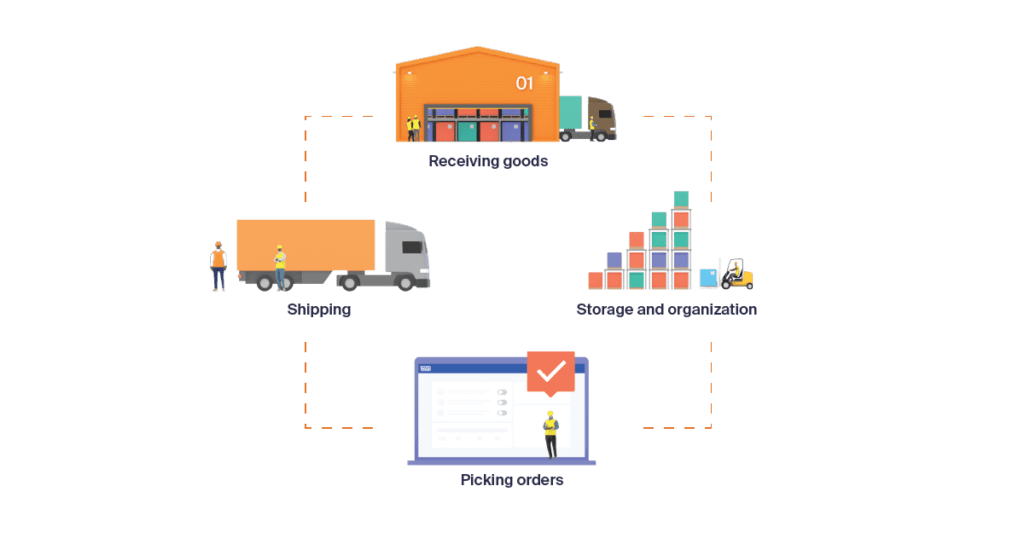

Stock Receiving

The journey begins with stock receiving, a critical step where Ware2Go sets the industry standard with our guaranteed dock-to-stock time of 48 hours. This expedited process helps ensure that goods are quickly moved from the receiving dock to the warehouse stock, significantly reducing the time to revenue and minimizing the risk of stockouts. Speed is crucial for outpacing competitors like Amazon, where delays can lead to a competitive disadvantage.

Storage

Once goods are received, we store them strategically within our warehouse. Our storage solutions are designed for space optimization and easy access, allowing smooth order-picking.

This stage is where the precision of warehousing and inventory management comes into play, ensuring that products are readily accessible when orders are processed.

Order Picking

Order picking, the next important process, involves selecting and preparing items for shipment. Meticulously manage this step to maintain accuracy and efficiency while directly impacting customer satisfaction through correct and timely deliveries.

Technologies like barcode scanners and warehouse management systems (WMS) are key in streamlining this process, reducing errors, and increasing how much we can process daily.

Shipping

Shipping is the final step, where orders are dispatched to their destinations. This phase underscores the importance of seamless integration between warehousing operations and logistics and ensures that products will reach customers promptly and in good condition.

Analytics at Every Stage

Accurate inventory tracking and forecasting are critical to all of these core processes. Maintaining real-time visibility into stock levels and using predictive analytics for demand forecasting are key parts of inventory management and warehousing.

We can optimize these core processes by leveraging technologies and tools like RFID, IoT devices, and advanced WMS, enhancing overall operational efficiency and customer satisfaction. This sort of strategic warehouse inventory management streamlines operations and serves as a cornerstone for business growth and customer loyalty.

How to Manage Warehouse Inventory and Inventory Management Challenges

Navigating the complex world of warehousing and inventory management presents a unique set of challenges that businesses need to correctly manage to keep their operations running efficiently. These challenges include using space, maintaining inventory accuracy, and effective labor management.

Space utilization is a common hurdle, especially as businesses scale. Maximizing warehouse space without compromising access and efficiency requires strategic layout planning and creative storage solutions. Vertical storage systems and modular shelving can dramatically enhance space use, allowing more inventory to be stored within the same area.

Inventory accuracy is another critical challenge, with discrepancies leading to stockouts, overstock, and lost sales. Inventory tracking systems like RFID technology and real-time data analytics can significantly improve accuracy. These technologies provide visibility into stock levels and movement, enabling informed decisions to quickly rectify any discrepancies.

Labor management in the warehouse is often complex, with fluctuating demand creating challenges when scheduling staff. Automation and training programs can enhance productivity and reduce reliance on manual labor. Technologies like warehouse robots and automated picking systems relieve the physical strain on workers and increase operational speed and accuracy.

Since supply chain disruptions are expected to occur every 3.7 years, lasting a month or longer, businesses must adopt a proactive approach to avoid these challenges. Building flexibility into warehousing and inventory management operations, such as scalable storage solutions and adaptable workforce strategies, can prepare businesses to adjust quickly in the face of disruptions.

Continuous improvement is critical for maintaining operational efficiency. Regularly reviewing processes, getting feedback from warehouse employees, and staying aware of new technological advancements can help identify areas for improvement. Adopting a culture of innovation helps keep warehousing and inventory management practices robust and responsive to changing markets and demand.

Future Trends in Functions of Inventory Management and Warehousing

As we look into the future of warehousing and inventory management, it’s clear that technological advancements will greatly impact how our work is done.

Automation and artificial intelligence (AI) are at the forefront of this transformation, streamlining operations and enhancing decision-making processes. These technologies let warehouses operate more efficiently, reducing human error and improving productivity. From automated storage and retrieval systems (ASRS) to AI-driven demand forecasting, technology is reshaping how businesses manage inventory and fulfill orders.

The Future of Fulfillment

Ware2Go’s “The Future of Fulfillment” report highlights some of these trends, providing insights from a comprehensive data study across consumers and sellers. This report gives you the knowledge to build stronger fulfillment strategies adaptable to the rapidly evolving shipping world.

Ware2Go’s Partnership With The Gap: A Case Study

Ware2Go’s partnership with Gap Inc.’s GPS Platform Services is a great example of adapting to future trends.

We collaborated and leveraged Gap Inc.’s extensive supply chain network with our advanced supply chain technology to offer small and medium-sized businesses access to enterprise-level fulfillment capabilities.

The partnership represents a significant shift towards co-warehousing solutions, providing scalable and efficient fulfillment options that cater to the changing needs of businesses, from apparel and footwear companies to international brands aiming to enter the U.S. market.

This strategic alliance shows the importance of collaboration and reflects the industry’s move towards more flexible, technology-driven solutions. As we join forces with GPS Platform Services, we set a new standard for warehousing and inventory management for the entire industry, demonstrating how innovation and partnership can drive growth and efficiency in an increasingly competitive marketplace.

Unlock Your Business’s Full Potential with Streamlined Warehousing and Inventory Management

Mastering warehousing and inventory management is crucial for navigating today’s complex market dynamics.

Businesses can enhance their efficiency, customer satisfaction, and ability to scale by understanding basic fulfillment processes and leveraging new industry trends.

As we showed in this article, integrating new technology will be key to future fulfillment strategies.

Our advanced solutions and expert guidance help transform your warehousing and inventory management processes. We can help streamline your operations, cut costs, and unlock your business’s full potential.

Reach out to Ware2Go, so we can help create a more efficient and responsive supply chain for your business. We’re here to help you scale effortlessly, reduce costs, and deliver a top-notch customer experience with our expert fulfillment and warehousing solutions.