With customers expecting increasingly fast shipping, traditional warehousing solutions often struggle to keep up. As the owner of a fast-growing brand, it’s a challenge you’ve likely run into yourself.

That’s where fulfillment centers, the unsung heroes of the supply chain, can help. This article explores how these third-party logistics services, used by Fortune 500 companies, are more than just inventory storage spaces. You can use them to provide seamless order processing and 1- to 2-day shipping windows for your eCommerce fulfillment needs.

By rethinking your approach to fulfillment solutions, you can transform your logistical challenges into strategic opportunities for growth. That’ll help ensure that your business continues to exceed the expectations of modern consumers.

Learn the difference between a fulfillment center, warehouse, and distribution center — plus how they all work together to build an efficient fulfillment network.

What Is a Fulfillment Center?

Fulfillment centers are warehousing facilities often run by third-party logistic providers. As part of fulfillment services, inventory is received, put away, and stored until customers make another order. When fulfillment providers receive an order, they pick, pack, and ship the product to the end customer.

Fulfillment warehousing typically isn’t intended for long-term storage. The longer that inventory sits on the shelf, the less profitable it is for you. That makes managing your inventory and prioritizing high-velocity SKUs more critical than ever.

Types of Fulfillment Centers

Different types of products have different requirements for warehousing and fulfillment. A fulfillment company sometimes specializes in certain product types, including:

- Big and Bulky – Heavier products can be hard to handle, requiring proper equipment and trained labor. They also require special racking and storage techniques.

- Small Picks – Small products like electronics and jewelry need storage solutions that minimize losses and mispicks.

- Climate Controlled – Large fulfillment centers don’t usually include air conditioning or heat. Some products can withstand a wide range of temperatures. However, cosmetics, vitamins, pharmaceuticals, and certain electronics need a temperature-controlled and humidity-controlled storage facility.

- Cold Chain – Perishable food items need a refrigerated storage facility called a cold chain fulfillment center.

There are also some unconventional models, like using stores as fulfillment centers.

What Is a Warehouse?

A warehouse is a large storage facility where goods are kept for extended periods, typically in bulk, until they are needed by manufacturers, wholesalers, or retailers. Its primary function is to store products efficiently, with less focus on frequent movement or individual order fulfillment.

Other key functions of a warehouse include:

- Storage – Warehouses provide space for both short-term and long-term storage of products. This includes raw materials, finished goods, or products waiting to be shipped to their next destination.

- Inventory Management – Warehouses track inventory levels, manage stock rotation, and ensure that products are organized and accessible. This helps in maintaining accurate records and efficient handling of goods.

- Receiving and Inspection – Goods are received from suppliers or manufacturers, inspected for quality, and verified against purchase orders. This step ensures that the products meet the required standards and are correctly recorded.

- Order Fulfillment – While warehouses primarily focus on storage, they may also handle basic order fulfillment tasks, such as picking and packing goods for shipment based on bulk orders or inventory needs.

- Distribution – Warehouses often play a role in preparing products for distribution, though they generally do not handle the final shipping to end customers. Instead, they consolidate goods and prepare them for transport to distribution centers or retailers.

Learn more about warehousing and fulfillment warehouse strategy with our Guide to Strategic Warehousing.

Fulfillment Centers vs. Warehouses

The primary difference between fulfillment centers and warehouses is their focus: Fulfillment centers are designed for processing and shipping individual customer orders, while warehouses are focused on the bulk storage of goods.

However, there are notable differences in the way that fulfillment centers handle order processing and returns management versus how warehouses manage inventory and basic order fulfillment tasks.

| Fulfillment Centers | Warehouses | |

| Primary Purpose | Manage and process individual customer orders | Store goods before they are distributed or sold |

| Key Functions | Order processing (picking, packing, shipping) Inventory management for order fulfillment Returns handling and customer service Efficient shipping to customers | Bulk storage of goods Inventory management Receiving and inspection of goods Basic order fulfillment tasks |

| Order Handling | Individual customer orders | Primarily bulk orders |

| Inventory Management | Real-time tracking for order fulfillment | Tracking stock levels for storage purposes |

| Technology | Advanced order management (OMS) and warehouse management systems (WMS) | Basic inventory management systems (IMS) |

| Automation | Often uses automation for picking, packing, and shipping | May use some automation but often relies on manual processes |

| Typical Users | E-commerce retailers Subscription box services | Manufacturers Wholesale distributors |

| Shipping | Coordinates shipping directly to customers | Prepares goods for distribution to other facilities or retailers |

Stores as Fulfillment Centers

The explosion of eCommerce and the decline of in-store shopping during the pandemic led many retailers to fulfill eCommerce orders directly from their stores. This major change required some reorganization and retraining of employees by retailers. But companies like Target turned their large store spaces into a competitive advantage.

According to a report by McKinsey, shoppers expect a similar experience whether they’re shopping in person or with online stores. Target’s ability to pivot stores into fulfillment warehousing centers allowed them to offer home and curbside pickup options.

Fulfillment Centers vs. Self-Fulfillment

If you’re considering using fulfillment center operations, you’re most likely handling your warehousing and fulfillment in-house right now. Let’s look at what you’ll gain by switching to a fulfillment center and some potential drawbacks to consider.

Advantages of Fulfillment Centers Compared to Self-Fulfillment

Choosing fulfillment centers over self-fulfillment can offer several advantages:

- Process Orders Faster – Fulfillment center staff are specialized in what they do and have their processes optimized. Ideally all orders should be fulfilled same-day in order to meet customer expectations for fast delivery and maintain compliance with major marketplaces like Amazon Prime.

- Avoid Storing Your Own Products – Fulfillment centers eliminate the need for your own storage facility. They also have the infrastructure to handle various products. You can offer a broader selection without worrying about physical space constraints or special handling requirements.

- Easily Scale Fulfillment Operations – As your business operations grow, fulfillment centers can easily accommodate your increasing order volumes. It’s simple to scale up without the logistical challenges of expanding your existing facility or relocating.

- Lower Staffing Costs – Outsourcing to a fulfillment center means you don’t have to manage warehouse staff. Your labor costs and the complexities of hiring, training, and managing a workforce will be reduced.

- Focus on Core Business Activities – With logistics and order fulfillment in expert hands, you can redirect your focus and resources toward core business activities, such as product development, marketing, and improving customer experience. Check out the video below for a real-world case study of how Ware2Go helped ECR4Kids outsource their fulfillment and allowed their team to focus on their strengths.

Disadvantages of Fulfillment Centers Compared to Self-Fulfillment

While fulfillment centers offer many advantages over self-fulfillment, there are a couple of trade-offs to consider:

- You Have Less Control – Outsourcing to a fulfillment company means giving up some degree of control over the warehousing and shipping processes. Lack of control, such as being unable to provide last-minute changes or fulfill special customer requests, could be a concern for businesses with highly specific product or shipping requirements.

- You Get Less Customization – Fulfillment warehousing centers might have limitations on the customization they can provide for packaging and shipping. Less customization can impact the brand experience for certain products.

Now that you know the advantages and disadvantages of fulfillment centers, let’s talk about how they differ from warehouses and distribution centers.

What are distribution centers?

A distribution center is a specialized facility within the supply chain designed to manage the flow of goods from suppliers to various destinations, such as retailers and wholesalers, or directly to customers. Unlike warehouses, which primarily focus on storage, distribution centers are optimized for the efficient sorting, consolidating, and routing of products to meet demand across multiple channels.

The key aspects of distribution centers include:

- Receiving and Inspection – Goods arrive from manufacturers or suppliers and are inspected for quality and accuracy. This step ensures that products are in good condition and match the ordered quantities.

- Inventory Management – Distribution centers maintain inventory levels, track stock, and manage reordering to ensure that products are available for distribution when needed.

- Order Fulfillment – Unlike fulfillment centers, which focus on individual customer orders, distribution centers handle bulk orders and consolidate goods for distribution to various locations, including retail stores and other distribution points.

- Sorting and Consolidation – Products are sorted based on destination and consolidated into shipments. This process ensures that orders are efficiently grouped and sent to the correct locations.

- Shipping and Distribution – Distribution centers coordinate the transportation of goods to their final destinations. This includes managing logistics and routing to ensure timely and cost-effective delivery.

Understanding these differences helps businesses choose the right type of facility or service based on their operational needs, whether they require bulk distribution capabilities or specialized order fulfillment services.

Fulfillment Center vs. Distribution Center

What are fulfillment centers in relation to distribution centers?

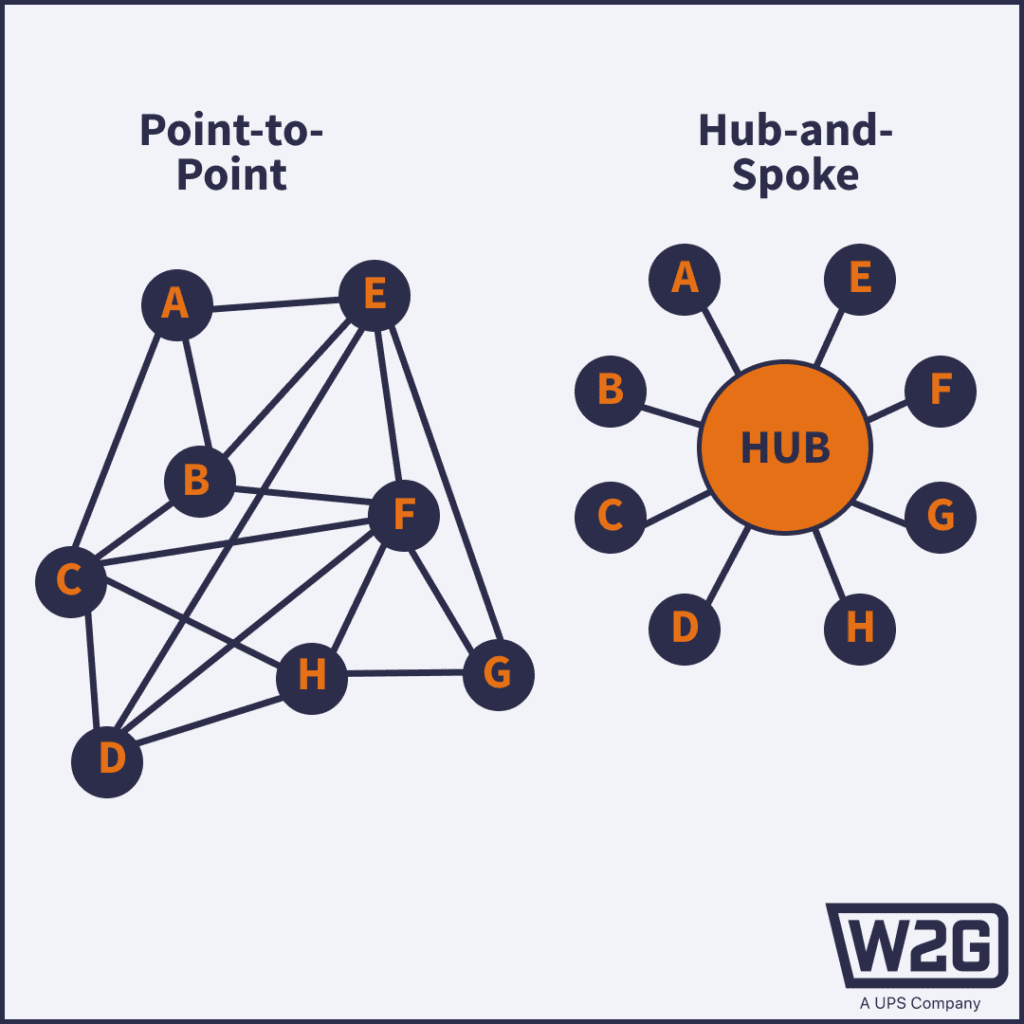

A distribution center acts as a hub within a network of fulfillment centers. For products manufactured overseas, a distribution center is often the first stop for inventory when it lands in the US.

In a hub-and-spoke fulfillment model, a distribution center takes inventory and strategically distributes it to fulfillment centers nationwide. The hub and spoke model gives your fast-growing brand more control over your inventory distribution.

No products go directly from a distribution center to the customer. You can think of the distribution center as the main internal fulfillment center that only exists to support all other fulfillment centers.

For example, imagine that your product sales surged in a specific area of the country. The hub-and-spoke model decreases the risk of stockouts by quickly channeling extra inventory from the distribution center to that area. The hub and spoke model also lowers the risk of making expensive long-zone shipments when demand spikes suddenly.

Frequently Asked Questions about Fulfillment Centers

Q: How do fulfillment centers adapt to seasonal demand fluctuations?

A: Fulfillment centers can quickly scale your storage space up and down as needed. They also use software with advanced forecasting for inventory replenishment to manage inventory levels and meet seasonal demands. These features allow fulfillment centers to deliver your product promptly while minimizing the risk of excess inventory and stockouts.

Q: Can fulfillment centers handle international shipping?

A: Yes, many fulfillment centers can manage international shipping. They offer global shipping solutions while helping you navigate the complicated world of customs, shipping costs, and regulations.

Q: What cutting-edge technologies do fulfillment centers use to enhance efficiency?

A: Fulfillment centers use AI, machine learning, and robotics technologies. These tools help optimize every step of the fulfillment process — from warehousing services and order processing to item tracking — for an overall more efficient process.

Q: How do fulfillment warehousing centers ensure product safety and security?

A: Fulfillment centers use strong security measures to help keep your products safe throughout the fulfillment process. These include surveillance cameras, access control, and inventory management systems to cover all safety elements.

Q: Can a fulfillment company support custom packaging and branding needs?

A: Many fulfillment centers offer customized packaging solutions. Custom packaging can help your business improve your brand through personalized packaging and branding elements.

Ware2Go’s Warehouse and Fulfillment Network

There are many advantages to fulfillment centers compared to self-fulfillment centers, such as relieving you of the stress of stockouts, overstocking, and dead stock. A fulfillment center can help with your business growth and provide a way for you to meet customers’ delivery expectations with faster shipping times.

Using machine learning and AI, Ware2Go’s network optimization tool, NetworkVu, shows you exactly where to place your inventory to get closer to your end customers. This lowers the time in transit on final mile deliveries for faster, more affordable shipping.

Download our step-by-step guide for more insights on creating a better fulfillment network and higher customer satisfaction.