Learn what just-in-time inventory is, its advantages and disadvantages, and how businesses can implement a JIT system to improve supply chain efficiency.

Hold too little and risk stockouts; hold too much and tie up capital in unsold products.

In this era of port delays and TikTok-viral demand spikes, inventory management has never been more challenging.

Download Ware2Go’s eBook to effectively implement efficient warehousing and fulfillment processes that support the JIT approach.

The cost of inefficient inventory management extends beyond storage fees—it impacts cash flow, slows growth, and can damage hard-won customer relationships. Even a single stockout can result in permanent customer loss.

Just-in-time inventory provides a solution that has transformed supply chain operations. This guide explains how just-in-time inventory works, its benefits, and how to implement it successfully in your business.

This guide explains how just-in-time inventory works, its benefits, and how to implement it successfully in your business.

What Is Just-in-Time (JIT) Inventory?

Just-in-time (JIT) inventory is a lean supply chain strategy designed to minimize waste and reduce inventory carry costs by replenishing stock as-needed to meet demand rather than holding safety stock (known as Just in Case inventory). By limiting safety stock, brands free up capital, streamline operations, and improve efficiency. However, JIT also introduces risks, particularly in volatile markets where supply chain disruptions can halt production or delay inbound shipments.

JIT originated from the Toyota Production System, revolutionizing manufacturing with its focus on efficiency and demand-driven inventory management. This guide will explore the advantages and challenges of JIT, along with best practices for businesses looking to implement it successfully.

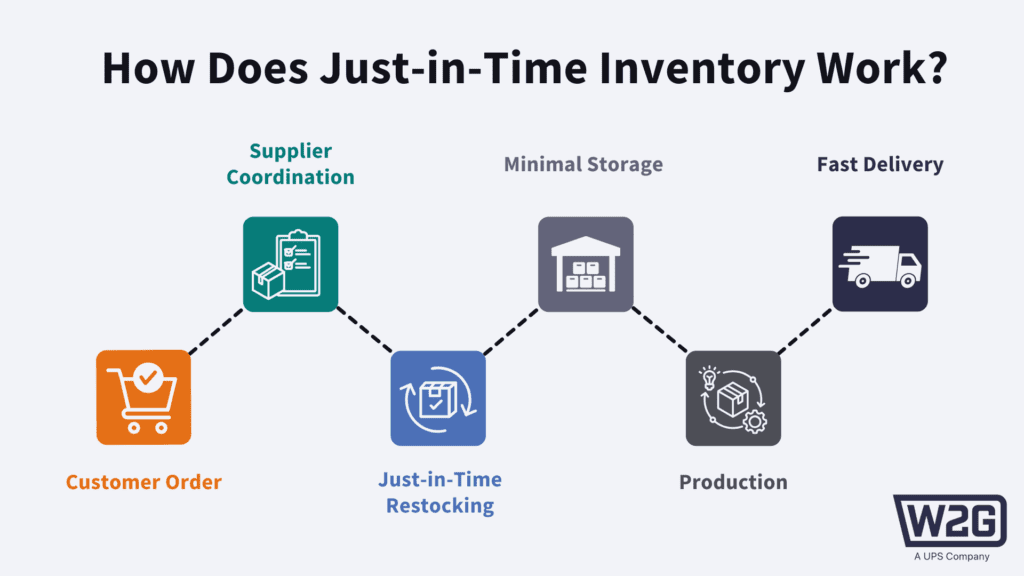

How Does Just-in-Time Inventory Work?

JIT inventory operates on a demand-driven model, ensuring that materials and products arrive precisely when they are needed—no sooner, no later. This approach reduces excess inventory, minimizes storage costs, and enhances operational efficiency. However, JIT requires accurate demand forecasting, strong supplier coordination, and agile demand planning to function effectively.

For example, a brand that sells grilling accessories and experiences a spike in demand in the summertime may order just enough inventory to meet demand based on the previous year’s order volume. If the brand is operating a JIT inventory strategy, they would inbound product shortly before the start of their peak season. In this scenario, it’s important to have complete inventory visibility to reduce the risk of backorders or cancelled orders due to stockouts if the brand does not plan on re-stocking.

Key Features of a JIT System

- Demand-driven restocking: Inventory is replenished only when required, reducing overproduction and excess stock.

- Supplier partnerships: JIT depends on reliable, fast supply chains and strong vendor relationships to maintain efficiency.

- Minimal storage & waste: Businesses keep only what they need, lowering holding costs and reducing waste.

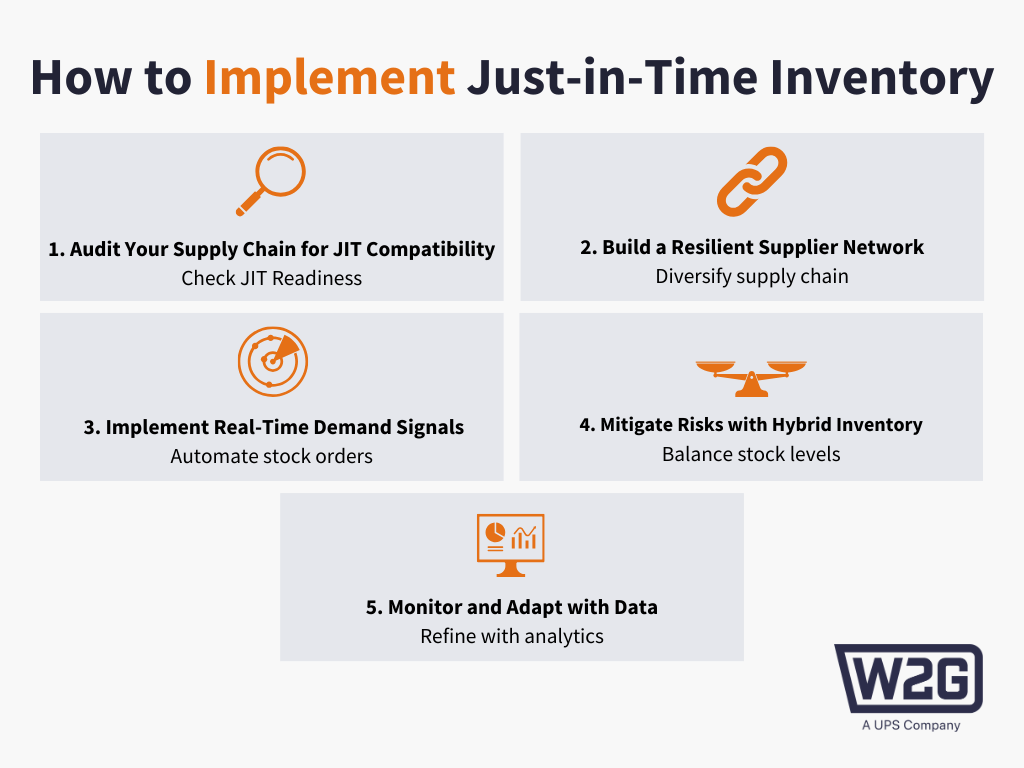

5-Step Implementation of Just-in-Time Inventory Management

1. Audit Your Supply Chain for JIT Compatibility

A successful JIT strategy starts with evaluating responsiveness and reliability of your supply chain to respond quickly to changes in demand. Supplier lead times are critical—JIT works best with vendors who can restock inventory within 48 hours to prevent costly stockouts. Partnering with agile suppliers ensures steady product flow without excess storage.

Partnering with a tech-enabled fulfillment company can enable you greater visibility into stock levels across your sales channels and warehouse locations to inform your procurement strategy for JIT inventory. For example, Ware2Go, a UPS warehousing and fulfillment company, leverages analytics tools to help businesses identify fast-moving SKUs versus slow-moving or obsolete inventory. Additionally, integrating an Order Management System (OMS) and Warehouse Management System (WMS) provides real-time inventory visibility, ensuring seamless demand forecasting and stock control.

2. Build a Resilient Supplier Network

JIT efficiency hinges on supplier reliability, making it essential to diversify vendors to reduce dependency and mitigate risk. A multi-supplier approach ensures that disruptions, such as shipping delays or raw material shortages, don’t halt operations.

Ware2Go’s vendor-managed inventory partnerships support flexible fulfillment strategies, allowing businesses to adjust stock levels dynamically. Negotiating flexible terms—such as bulk discounts on smaller, more frequent shipments—further enhances supply chain adaptability without overloading inventory.

3. Implement Real-Time Demand Signals

For JIT to work effectively, sales channels must be synced with an advanced OMS to trigger automatic stock replenishment. Ware2Go’s OMS connects demand signals directly to inventory, ensuring seamless replenishment and reducing manual oversight.

Setting reorder thresholds automates purchase orders when stock levels hit a predefined point, preventing shortages and improving supply chain responsiveness. This proactive approach keeps inventory lean without sacrificing potential sales or delaying order fulfillment speed.

4. Mitigate Risks with Hybrid Inventory

While JIT minimizes excess stock, maintaining a 10–15% buffer stock for top-selling SKUs helps prevent stockouts during demand spikes or supply chain disruptions. This strategic reserve acts as a safeguard without straying from lean principles.

For niche or low-volume SKUs, drop-shipping offers a cost-effective solution. Instead of warehousing slow-moving items, businesses can fulfill orders directly from suppliers, reducing carrying costs while maintaining product availability.

5. Monitor and Adapt with Data

A data-driven approach is essential for continuous JIT optimization. Tracking key KPIs—such as inventory turnover rate, order accuracy, and supplier lead times—provides insights into performance and areas for improvement.

Regular monthly reviews help businesses adjust safety stock based on seasonal demand trends, ensuring the right balance between lean inventory and order fulfillment reliability. By continuously refining JIT strategies with real-time data, businesses can maintain agility and resilience in a dynamic market.

What Are The Advantages and Disadvantages of Just-in-Time Inventory?

Just-in-time (JIT) inventory offers a leaner, more cost-effective alternative to traditional purchasing and production models. By reducing excess stock and focusing on real-time demand, JIT helps businesses stay agile while reducing operating costs. However, the strategy also comes with challenges, particularly when faced with supply chain disruptions or fluctuations in demand. Below, we explore the key advantages and disadvantages of JIT inventory management.

Advantages of JIC Inventory

Shorter Production Runs

With a JIT strategy, you’re producing goods in smaller batches, allowing you to pivot more easily. Instead of committing to large-scale production runs, manufacturers can respond dynamically to shifts in demand, reducing waste and excess stock. Just-in-time deliveries also shorten overall production lead times by ensuring that components arrive exactly when needed, eliminating storage bottlenecks.

Reduced Inventory Carrying Costs

By maintaining minimal inventory levels, JIT significantly reduces storage costs, insurance expenses, and the risk of obsolescence. With this streamlined approach, you can allocate resources more efficiently while reducing capital tied up in unsold inventory.

Improved Cash Flow

Because JIT minimizes the upfront investment in raw materials and finished goods, more of your capital is available to invest in other business operations like product development and marketing. This financial flexibility is especially valuable in industries with fluctuating demand or tight margins.

Better Customer Satisfaction

Faster production cycles and efficient order fulfillment help businesses meet customer expectations for speed and reliability. JIT also allows for more customized production, enabling businesses to respond to consumer demand on a more granular level. For example, if a particular color of a product is selling faster than the rest, you can increase production of that single SKU to ensure availability of your most popular items.

Enhanced Quality Control

With JIT, manufacturers focus on smaller, more frequent production runs, reducing the risk of defects and ensuring greater quality control. When you receive materials in precise quantities as needed, you can quickly identify and address quality issues, preventing large-scale defects or recalls. Frequent deliveries also promote continuous supplier accountability, leading to higher product quality and less waste.

Disadvantages of JIC Inventory

Increased Risk of Stockouts

Keeping inventory levels low makes your business more vulnerable to supplier delays and sudden spikes in demand. Without buffer stock, even minor disruptions can lead to stockouts, affecting sales and customer satisfaction. To mitigate this risk, Ware2Go, a UPS-owned warehousing and fulfillment provider, provides full inventory visibility at the SKU-level to better anticipate and prevent stockouts.

Higher Operational Complexity

Coordinating suppliers, production schedules, and logistics in a JIT system requires advanced planning and communication. Brands must rely on real-time inventory tracking and seamless supplier communication to prevent bottlenecks.

Potential for Increased Costs

Without proper planning, frequent small-batch deliveries can drive up transportation expenses compared to bulk shipments. However, with a fulfillment provider like Ware2Go you can aggregate your shipping volume with other brands to negotiate better rates with freight carriers.

Additionally, while JIT reduces excess inventory, mismanagement can still result in dead or damaged stock with limited recovery options, impacting profitability.

Limited Flexibility

Operating with minimal inventory leaves little room for handling unexpected delays or demand fluctuations. Businesses with volatile sales cycles may struggle to scale up production quickly under JIT constraints. To reduce guesswork, Ware2Go’s AI-driven demand forecasting tools help businesses predict trends and adjust procurement strategies proactively, ensuring they remain agile in changing market conditions.

Which Industries Benefit the Most from Just-in-Time (JIT) Inventory?

Just-in-time (JIT) inventory is widely used across industries that prioritize efficiency, cost reduction, and rapid response to demand fluctuations. From automotive to eCommerce, businesses leverage JIT to streamline operations, minimize waste, and improve supply chain agility.

1. Automotive Industry – Toyota

Toyota pioneered JIT through its Toyota Production System (TPS), revolutionizing automotive manufacturing by reducing excess inventory and optimizing production flow. Instead of stockpiling auto parts, Toyota receives components precisely when needed, preventing overstocking and unnecessary storage costs. This lean manufacturing approach enables Toyota to maintain high efficiency across its global supply chain while adapting to shifting market demands.

2. Technology Industry – Dell

Dell’s JIT strategy allows it to stay ahead of rapid technology advancements and avoid outdated inventory. By leveraging a direct-to-consumer model, Dell assembles laptops and desktops only after receiving customer orders. This approach minimizes excess stock, reduces warehousing costs, and ensures that customers receive the latest technology without delays.

3. Fashion & Retail Industry – Zara

Fast fashion brand Zara relies on JIT to produce limited inventory batches, enabling quick responses to changing fashion trends. Instead of committing to large seasonal production runs, Zara’s supply chain is designed to deliver new designs to stores within weeks, not months. This strategy minimizes unsold inventory, reduces markdowns, and keeps the brand at the forefront of fashion trends.

4. eCommerce & Logistics – Amazon

Amazon optimizes its fulfillment operations using JIT-driven logistics, ensuring that products move quickly through its supply chain while minimizing storage costs. By leveraging predictive analytics and demand forecasting, Amazon maintains an extensive product catalog without excessive warehousing. This approach allows for faster delivery times and more efficient inventory management, benefiting both sellers and consumers.

5. Manufacturing Industry – Boeing

Boeing applies JIT principles in aircraft production to reduce inventory costs and streamline assembly. With thousands of components sourced from global suppliers, Boeing coordinates just-in-time deliveries to ensure that parts arrive precisely when needed for production. This minimizes excess stock while maintaining a steady and efficient production process, ultimately reducing costs and optimizing resource allocation.

Is Just-in-Time Inventory Right for Your Business?

Just-in-time (JIT) inventory offers significant cost savings and efficiency, but it’s not a one-size-fits-all solution. It’s essential to assess your supply chain stability, supplier reliability, and technological infrastructure to determine whether JIT is the right fit for your business.

Key Criteria for JIT Suitability

Demand Stability

JIT works best for businesses with predictable sales patterns, typically around a 10% monthly fluctuation range. Industries like automotive manufacturing and subscription-based services benefit from steady, repeatable demand, ensuring inventory arrives precisely when needed without unnecessary overstock.

Supplier Reliability

For JIT to succeed, suppliers must provide consistent quality and meet lead times of 48 hours or less. When you’re running a tight supply chain with little to no safety stock, a single delay can disrupt production or fulfillment.

Real-Time Data Infrastructure

A robust Order Management System (OMS) and Warehouse Management System (WMS) are essential for real-time inventory visibility. Retailers, for example, can use point-of-sale (POS)-driven restocking to replenish inventory dynamically, preventing stockouts while keeping storage lean.

When JIT Excels

- High-Volume, Low-Variability Production – Automotive manufacturers like Toyota use JIT for efficient, repetitive assembly line operations.

- Perishable Goods – Grocery suppliers rely on JIT to minimize spoilage, receiving fresh inventory through daily deliveries.

- Space-Constrained Operations – Urban eCommerce fulfillment centers leverage JIT to optimize limited warehouse space while maintaining rapid order fulfillment.

Decision-Making Checklist

If you’re considering shifting to a JIT inventory management strategy, first ask yourself the following questions about your business:

- Is demand predictable (±10% monthly fluctuation)?

- Can suppliers meet ≤48-hour restocking windows?

- Do you have real-time inventory tracking?

- Are you in an industry prone to sudden disruptions (e.g., healthcare)?

If you answer “No” to two or more of the questions above, a hybrid JIT model may be a better fit.

The Hybrid Approach: JIT + Safety Stock

JIT isn’t always viable on its own, especially in industries with seasonal demand shifts or long lead times for critical components. A hybrid approach balances lean inventory with strategic stock reserves.

When to Use a Hybrid Approach:

A hybrid inventory approach is particularly useful in scenarios where demand fluctuations or supply chain constraints make pure JIT impractical. During seasonal demand spikes, such as the holiday shopping season, retailers maintain buffer stock to accommodate sudden surges in orders and prevent stockouts.

Similarly, industries with long lead times for critical components, such as electronics and automotive manufacturing, rely on safety stock to mitigate supply chain disruptions. For example, semiconductor shortages highlighted the risks of relying solely on JIT, prompting manufacturers to stockpile essential components to ensure production continuity.

How Hybrid Inventory Works:

Businesses adopting a hybrid model typically maintain a 10–15% buffer stock for their top-selling SKUs while using JIT for everyday replenishment.

For example, fast fashion brands like Zara apply JIT to staple fashion items while keeping safety stock for trending designs that may see unexpected demand surges. By blending JIT with strategic reserves, businesses can optimize efficiency while safeguarding against supply chain disruptions..

JIT Inventory FAQs

Is JIT suitable for small businesses?

Yes, JIT can be a great fit for small businesses, especially those with predictable demand patterns and reliable suppliers. By minimizing inventory holding costs, small businesses can free up capital for other investments. However, JIT requires strong supplier relationships and real-time inventory tracking to avoid disruptions. For businesses with unpredictable demand or long supplier lead times, a hybrid JIT approach with safety stock may be a better option.

How do you handle sudden demand spikes?

Managing demand spikes in a JIT system requires proactive planning. Businesses can set reorder thresholds based on historical sales data and seasonal trends to trigger automatic restocking before demand surges. Partnering with suppliers that offer rapid replenishment, ideally within 48 hours, is also crucial. For industries with extreme fluctuations, maintaining a small buffer stock for top-selling SKUs can help prevent stockouts without negating JIT’s efficiency benefits.

What tech is essential for JIT?

A successful JIT strategy depends on real-time inventory visibility and automated replenishment. Essential technologies include an Order Management System (OMS) to sync sales channels, a Warehouse Management System (WMS) for inventory tracking, and demand forecasting tools powered by AI. Retailers often integrate their Point-of-Sale (POS) systems with inventory management software to enable automatic restocking based on real-time sales data.

What’s the difference between JIT and Lean manufacturing?

JIT is a component of Lean manufacturing, but they are not the same. JIT focuses specifically on reducing inventory waste by ensuring materials and products arrive only when needed. Lean manufacturing, on the other hand, is a broader methodology aimed at eliminating all types of inefficiencies, including excess inventory, production bottlenecks, and quality issues. While JIT optimizes inventory flow, Lean manufacturing improves the entire production process, from supply chain management to customer delivery.

Optimize JIT Inventory with Ware2Go’s Expertise

Think JIT is just about slashing costs? Leaner inventories do save money, but the real power of just-in-time lies in maximizing efficiency, improving cash flow, and staying flexible when markets shift overnight. That means accurate demand forecasting, dependable supplier partnerships, and laser-focused tracking systems must align—or you risk stockouts and rising expenses. Ware2Go helps you sidestep those pitfalls.

Looking for a partner to support your business with an efficient inventory management strategy like JIT? Partner with Ware2Go to leverage our nationwide fulfillment network and predictive inventory tools. Guarantee 1-2 day delivery while cutting storage costs by up to 30%.