This video has our top three tips to prepare for a successful Peak holiday shopping season in spite of port congestion, warehouse capacity, and inventory concerns.

This video has our top three tips to prepare for a successful Peak holiday shopping season in spite of port congestion, warehouse capacity, and inventory concerns.

Port congestion and warehouse space are top of mind for everyone again this year. While the supply chain is in better shape than it was this time last year, merchants still face challenges ahead of them as they plan for Peak holiday shipping season. These are the top three things you should be doing right now to ensure a successful Peak in spite of port congestion and low warehouse vacancy rates.

The most popular warehousing markets are Southern California and New Jersey. While the nationwide vacancy rate hovers around 4%, the vacancy rate in New Jersey is around half that, and availability in Southern California is even lower.

These coastal markets are close to the country’s busiest ports – which are often the most affordable for small to mid-sized businesses (SMBs) who may be importing only a container or two. They’re also located in heavily populated areas, giving them great 1- to 2-day ground shipping coverage.

Because these markets are in such high demand, they’re also very expensive. Keeping slow-moving inventory in these regions will eat up margin with inventory carry costs. It’s time to move slower-moving SKUs into deep storage in the center of the country to decrease storage costs and free up capacity for high-velocity seasonal inventory.

The current labor market is tight. The best way to ensure you have the labor to meet seasonal spikes in demand is to communicate with your fulfillment partner. An in-depth demand forecast includes your historical sales data, market and industry trends, and promotional schedules.

When your fulfillment partner is prepared for changes in order volume, they can secure the appropriate labor and re-slot inventory for more efficient pick times if necessary.

There are record levels of inventory in this country – a bullwhip effect caused by over-buying in response to last year’s supply chain shortages and a change in consumer buying patterns. It may feel risky to liquidate valuable inventory, but the truth is, if it hasn’t turned in 120 days or more, it’s costing you more to store it than you’ll ever make back on a sale.

What’s more, all that valuable warehouse space being occupied by obsolete inventory represents a huge opportunity cost. If you liquidate, you’ll free up capacity for products that will actually sell at a profitable rate.

Heading into a third pandemic holiday season, merchants were prepared for supply chain challenges, and many have already planned ahead. At Ware2Go, we surveyed merchants across all sectors to learn their strategies for navigating another unprecedented year.

A full 95% of merchants said they had to adjust their supply chain planning in response to disruptions and market conditions. Their biggest concern was inventory planning, with 68% saying they changed their inventory ordering strategy in some way this holiday season.

Even though they changed their strategy, many merchants still have concerns around their Peak season inventory, including:

Port congestion can weigh more heavily on SMBs who often don’t have the same negotiating power as major retailers who import full ship-loads of cargo and are much more attractive to to freight forwarders.

This Peak season, Ware2Go is helping SMBs in three distinct ways:

Our network of partners enables us to receive imports at any US port, including rerouting to a different port. Dwell times continue to slow down supply chains, and many merchants need the option to import into secondary ports like Houston, Savannah, Oakland, or Richmond to name a few.

Rail transportation service disruptions can slow down inbounds and make shipping cross-country prohibitive. Transloading containers at a facility near a terminal like the Port of Los Angeles speeds up time to inbound by avoiding congested railways.

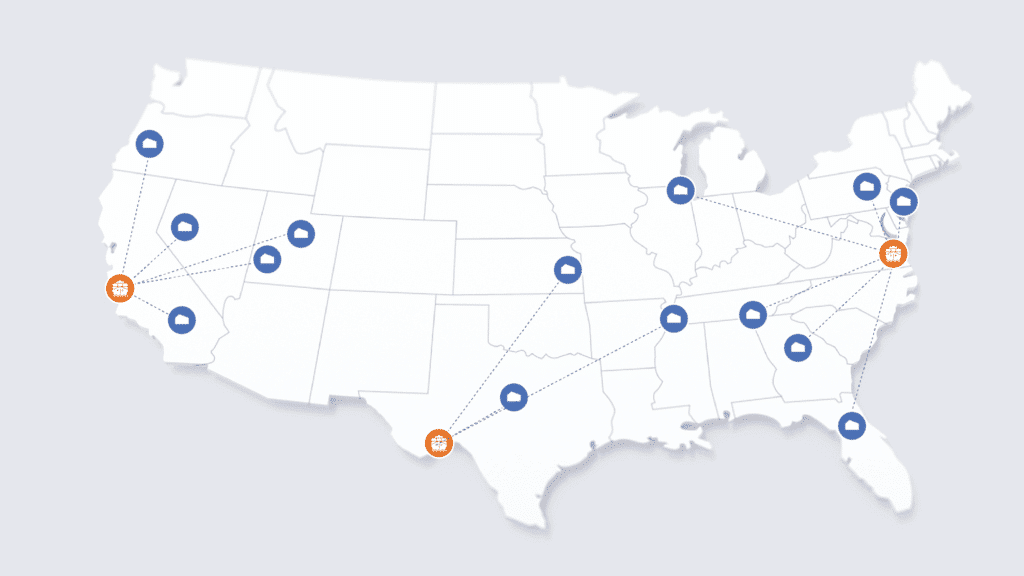

After pallets are broken down and contents are sorted and re-palletized, they can be transported over the road (OTR) via truckload or domestic container. From the transload facility, they are dispersed directly to fulfillment centers across the country.

In spite of years of supply chain disruptions, consumer expectations for 1- to 2-day shipping have not waned. Ware2Go is helping merchants meet these expectations without eroding margins by positioning inventory across a nationwide distributed warehouse network.

Inventory distribution lowers time in transit (TNT) on final mile deliveries to ensure ground shipping within 1- to 2-days.This enables merchants to meet the customers’ expectations for fast shipping without relying on costly solutions like Next-Day Air.

The ongoing supply chain challenges have taught merchants that flexibility and resilience are the most important qualities of a supply chain solution.

In order to have a successful Peak season in spite of port congestion, warehouse capacity, and inventory concerns, merchants need a strategic supply chain partner with an end-to-end solution.

Looking for more tips for Peak season planning? Check out our ultimate Peak planning resource center. Looking for a flexible end-to-end supply chain solution? Reach out to one of our in-house experts today.