Learn how SKU management helps businesses of all sizes maintain control of their sales and profitability while meeting consumer expectations for 1- to 2-day delivery.

Learn how SKU management helps businesses of all sizes maintain control of their sales and profitability while meeting consumer expectations for 1- to 2-day delivery.

A SKU (or, stock keeping unit) consists of multiple codes made up of letters and numbers that indicate a product’s characteristics, such as color, size, brand, and location. Accordingly, a well-thought-out SKU management system is an essential aspect and best practice of accurate inventory management

A SKU management system is the process of creating, maintaining, and updating an alphanumeric structure that allows for the identification, organization, and tracking of inventory. SKU management also helps you gain deeper insights into the profitability of your business. Without these tracking measures in place, you could run the risk of mistaking sales velocity for profitability and ultimately, sell yourself out of business.

Sellers with a SKU-level view of profitability can effortlessly track inventory down to individual product variants and confidently make better business decisions. Knowing their best and worst performing SKUs, fast growing merchants can forecast how increases in inventory and marketing spend will generate greater sales volume.

On the contrary, those who do not take SKU management seriously may invest inappropriately in high-margin or underperforming products instead of reducing inventory and marketing budgets – or even eliminating under-performing SKUs from their catalog completely.

User-friendly SKU management is the foundation for a successful inventory management setup that integrates Warehouse Management System (WMS), Order Management System (OMS), and Transportation Management System (TMS) data.

Powered by artificial intelligence (AI) and machine learning, optimized inventory management makes sellers more nimble and adaptable in today’s rapidly changing omnichannel sales environment. According to McKinsey, the power of AI to understand the relationship between large volumes of data enables merchants to make quicker decisions around inventory planning and margin optimization.

Also, a clear SKU system reduces human error during picking the pick, pack, and ship process. You can also use inventory management software to generate inaccuracy reports to identify bottlenecks and poor inventory control, such as mislabeled, damaged, and out-of-stock items.

Having a unique SKU for every product variation is a crucial part of optimal inventory management. Specific and unique SKUs enable more accurate demand forecasting using machine learning and AI to analyze historical sales and seasonality patterns.

Additionally, this data helps merchants avoid stockouts and backorders, which damage brand equity and Customer Lifetime Value (CLV). Sellers who understand when to re-order the most profitable inventory and where to stock inventory closest to their top buyers can also deliver on consumer expectations for fast shipping.

Better buyer insight benefits everyone. Customers get the low-cost, fast shipping that is expected from brands of all sizes today and merchants attain greater top-line revenue.

Holistic Hound put buyer insight to work and found a more efficient method for reaching their partners. After finding that 40% of product shipped to wholesalers on the East Coast was taking 4-5 days to arrive, the pioneer in the CBD oil for pets industry now utilizes a nationwide warehouse network to guarantee 1-2 day order fulfillment to their best customers.

The outcome of strong SKU management incorporated into a technology-first inventory management system is higher revenue and better gross margins. Merchants can stock their most popular SKUs in the right quantity in the optimal location before purchase, meeting consumers’ increasing demand for 1-2-day shipping without exhausting margins.

A stock keeping unit (or SKU) consists of a series of letters and numbers that at first glance may seem randomized. However, a properly formatted SKU includes multiple codes that indicate a product’s unique characteristics, such as color, size, brand, and location. These codes communicate important information about your products to inventory managers, warehouse staff, and customer success during the inbounding, picking, and packing processes.

A well-thought-out SKU management system is easy to understand and helps your team quickly identify products correctly. This ensures more accurate inventory cycle counts, faster fulfillment times, and acts as a safeguard against mis-picks, saving you time and money.

Another common code for identifying inventory is a Universal Product Code Number (or UPC number). The UPC number is the 12 digit number listed below the barcode and helps retailers and distributors track inventory through their Point of Sale systems. While SKUs are unique to an individual retailer, UPC numbers are universal to a product regardless of who the seller is.

Ultimately, you know your products best and should include the information within your SKUs that you think most clearly defines your products. The way you format your SKUs tells your fulfillment partner what is most important about your products and how to quickly and accurately identify them and differentiate them from similar variations.

Some qualities of your products that may be unique and easily identifiable are:

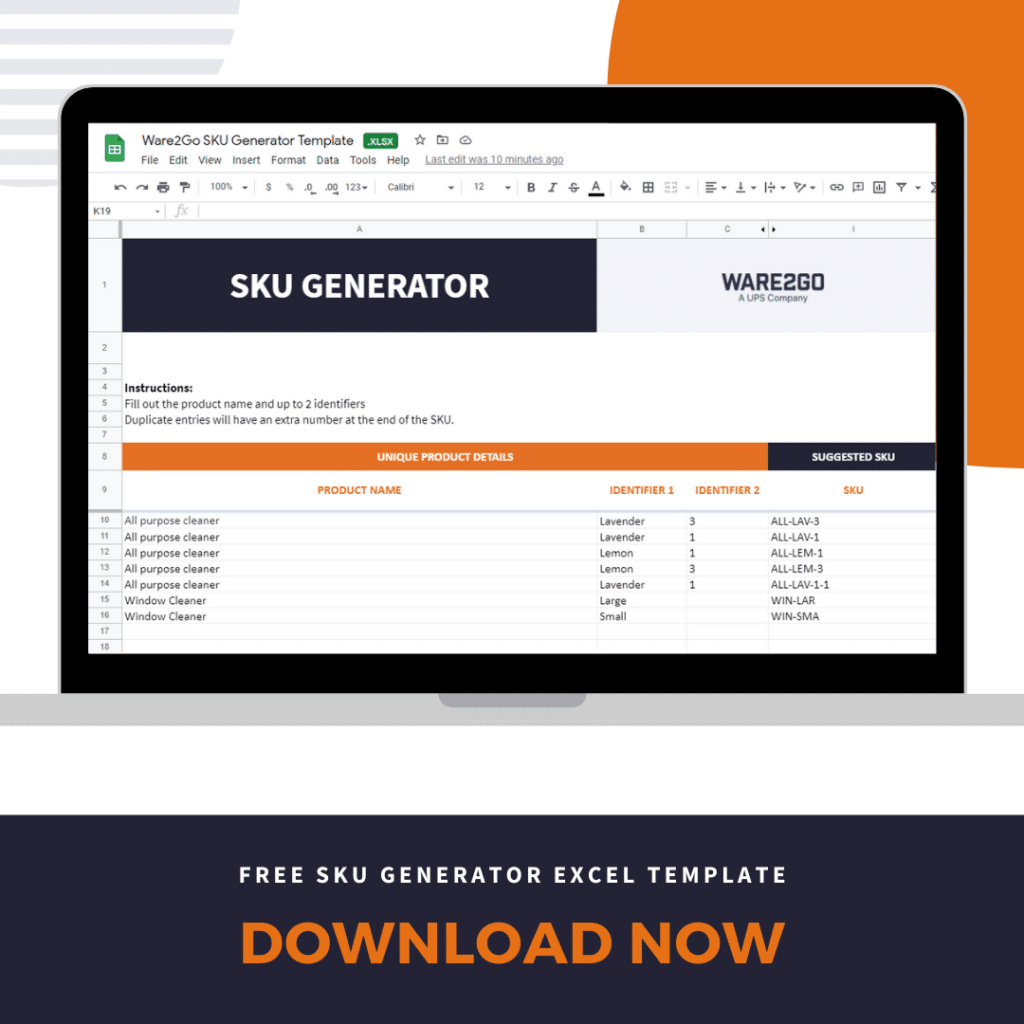

Most merchants choose up to three unique identifiers, shortened (if needed) to 3 or 4 characters, and separated by dashes. In all, a SKU should not be more than 12 characters long. For example, if one of your product lines is an all-purpose cleaner that comes in either a lavender or lemon scent and can be bought as a single unit or in a pack of 3, you may choose to structure your SKUs like this: ALL-LAV-3

While there’s no hard and fast rule for creating your SKUs, there are some general inventory management best practices that will make them cleaner and more manageable — both for employees and warehouse partners as well as your inventory management software.

A straightforward, easy to understand product information tracking system will help you make more informed procurement decisions, better track inventory levels across all of your sales channels, and deliver an optimum customer experience.

Following SKU best practices helps you avoid stockouts and lost revenue due to discrepancies in inventory cycle counts and inaccurate data. Additionally, in-depth inventory reporting helps you avoid re-ordering slow-moving, unpopular products that sit in the warehouse, tying up working capital in unnecessary storage costs that could support higher profit inventory.

The benefits of efficient SKU management are evident; however, maintaining gross profit by SKU in a spreadsheet is not effective or sustainable. Similarly, creating an automated, scalable framework is an expensive, daunting proposition for small-to-medium-sized businesses (SMBs) that do not have analysis capabilities readily at hand. In the past, these resources included an in-house data analyst, database administrator, and full stack development to pull data from multiple sources and display it all in a visualization system.

For this reason, more SMBs are turning to technology-first logistics providers to handle this heavy data and integration lifting. These partners aggregate data from all OMS, WMS, TMS, CRM and online shopping cart sources into one intuitive platform, giving SMB’s game changing insight that lowers COGS and improves profitability.

For weekly insights on supply chain and inventory management right in your inbox, sign up for Ware2Go’s monthly newsletter.